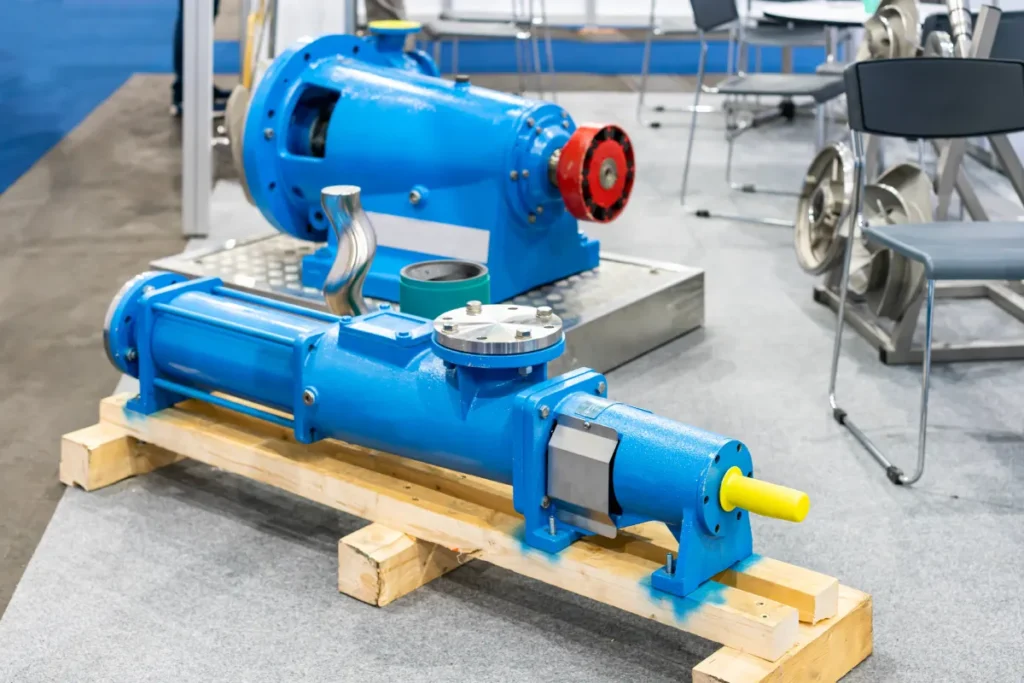

Sludge pumps play an integral role in industries where efficiency, dependability, and uptime have a direct influence on productivity and operating costs. For example, mining operations that handle abrasive tailings, oil and gas facilities that oversee drilling muds, and municipal systems that process sewage and rainwater. These pumps are the foundation of the fluid handling system. In defense and naval applications, the durability of sludge pumps is crucial, as equipment failure can disrupt mission-critical activities.

Despite being a critical component in sludge handling, these pumps are subjected to some of the most challenging conditions in engineering. They are exposed to abrasion from suspended solids, corrosion from chemically aggressive fluids, and unanticipated downtime due to premature desludging, resulting in increased maintenance costs and the risk of prolonged downtime.

The key to addressing any of these issues can be linked to two factors: wear resistance and proper material selection. By aligning the pump’s design and material with the type of sludge being pumped, the user can expect a longer service life of the pump, reduced maintenance downtime, improved return on investment (ROI), and other potential benefits. For decision-makers, it is clear that the value of getting this selection correct significantly outweighs the cost of the pump, even before the pump is used. This pump is not designed correctly, based on the nature of the sludge, which will certainly compromise its service life, reliability, and operational continuity.

Understanding the Demands of Heavy-Duty Sludge Pump Applications

The environments in which sludge pumps operate vary, as do the challenges and demands to which they are subjected. A pump designed for sewage will encounter fibrous solids and biological wastes, while a pump handling industrial effluent may contend with extremely corrosive chemicals. In mining operations, sludge pumps work with dense slurries and sharp abrasive particles. Since stormwater applications often involve varying solids loading and hydraulic conditions, the equipment is also used in challenging conditions.

These operational stresses dictate that wear resistance and materials compatibility are critical factors. Abrasive solids can be abrasive due to high solids concentrations, while corrosive fluids may damage or degrade conventional metals. Also, fluctuating temperatures can be an additional complexity for the pump suitability. In these environments, a pump can lose efficiency quickly without proper engineering solutions, resulting in costly replacements or repairs.

Therefore, procurement and engineering managers must consider more than just the up-front costs of the equipment. While a budget purchase may seem appealing, the ongoing costs will often outweigh the initial price due to premature wear and downtime. Choosing a sludge pump designed with wear-resistant alloys, protective elastomers, or corrosion-resistant coatings can assure a predictable performance life and useful service intervals. For projects with additional flexibility requirements, hiring a sludge pump can be a viable option, providing immediate access to engineering equipment without the upfront purchase commitment. A submersible sludge pump also operates directly in the liquid (faeces) and can be a sound solution for sites or remote access where space is constrained.

By aligning pump type, material selection, and procurement strategy with the actual operating conditions, an organization can protect the dual pursuit of performance and ROI. Whether through owned asset commitments or temporary options, such as a sludge pump for hire, the foundation of sustainability lies in understanding the operating conditions of a challenging application.

Key Factors in Selecting Sludge Pumps

When assessing these submersible sludge pumps for challenging environments, purchasing groups and engineering managers must evaluate a multitude of performance and durability factors. A poorly made decision can lead to inefficiency, expensive downtime, or maintenance issues.

Flow Rate and Total Dynamic Head (TDH):

One of the first considerations is ensuring the pump can handle both average and peak operating conditions. Oversizing leads to wasted energy, while undersizing results in system stress and premature failure. A properly rated sludge pump balances flow capacity and TDH to deliver consistent performance without excessive wear.

Solids-Handling Capability:

Sludge pumps are expected to pass abrasive and fibrous materials without clogging. This requires careful attention to impeller design and passage size. Features such as vortex impellers or recessed channels enable the passage of large solids, thereby reducing blockages and downtime.

Operating Environment:

Conditions such as fluid temperature, abrasiveness, and corrosiveness strongly influence pump material selection. In mining, highly abrasive tailings often require high-chrome alloys, while industrial effluents with acidic or alkaline content necessitate corrosion-resistant stainless steels. Submersible sludge pump designs must also withstand full immersion while maintaining reliable seal integrity.

Energy Efficiency:

Modern submersible sludge pumps can be paired with variable frequency drives (VFDs) to adjust their performance in real-time. This allows operators to optimize energy use across fluctuating loads, reducing lifecycle operating costs.

Procurement Flexibility:

Not every project requires permanent investment. For short-term or seasonal demands, a sludge pump for hire provides a cost-effective solution. Organizations can access high-quality equipment when needed, avoiding the capital expense of outright purchase. This flexibility is particularly valuable for municipal projects, temporary bypass systems, or emergency applications.

Wear Resistance in Sludge Pumps: Where It Matters Most

Even the best-designed pumps are subject to constant wear due to abrasive solids and corrosive fluids. Understanding where wear occurs and its impact on performance is crucial for extending service life and minimizing downtime.

Key Wear Components:

- Impeller: The primary energy transfer component, exposed to high levels of abrasion.

- Volute/Casing: Directs flow and absorbs erosion from moving particles.

- Liners (Front and Back): Protect the pump housing and extend equipment longevity.

- Throatbush: One of the most wear-prone areas due to slurry discharge velocity.

- Shaft Sleeve: Shields the shaft from slurry contact and protects the seal from we and tear.

- Seals and Bearings: Maintain shaft alignment and prevent leakage, which is often compromised by the intrusion of solids.

Impact on Performance and Maintenance:

Excessive wear reduces hydraulic efficiency, resulting in higher energy costs and ultimately leading to system shutdowns. For critical industries, unscheduled downtime can result in substantial financial losses. Submersible sludge pump systems, for example, may be particularly costly to retrieve and repair if wear is not anticipated.

Planning with Predictable Wear Patterns:

Monitoring areas of common wear provides operators the ability to perform preventive maintenance before any failures occur. This minimizes emergency repairs and helps maintain uptime on sewer systems. Working with suppliers that provide reliable spares, along with clear wear-life data, will enable teams to plan, budget, and maintain optimal performance. For interim or backup opportunities, a sludge pump for hire can fill the gap while a primary operator is being serviced, ensuring operations run smoothly.

Material Selection Strategies for Long-Term Performance

Choosing the correct construction materials is a tough decision in ensuring the long-term life of pumps and that the slurry is delivered safely and effectively. Different operating environments require different levels of abrasion and or corrosion resistance. If inadequate construction materials are used, the service life will be shortened, maintenance requirements will increase, and operations will be interrupted.

High-Chrome Alloys:

In situations where abrasive slurries and high solids content are present, such as in mining and dredging, high-chrome alloys excel in the wear environments that occur. The hard surface will resist erosion, extending the life of the impeller and liner, even with constant hits and impacts from coarse particles. Many pumps are designed to operate in these conditions and utilize high-chrome alloys. These high-chrome alloys minimize unplanned downtime and enhance performance in the process.

Hardened Stainless Steels:

The corrosion resistance of materials is generally more important than abrasion resistance in applications such as municipal wastewater treatment or chemical processing. Hardened stainless steels can be used to protect structures in highly aggressive effluents, where mild steels would quickly degrade. The use of hardened stainless steels means that allude pumps used in corrosive environments have increased service lives due to part degradation.

Elastomers and Ceramics:

Elastomers offer a level of flexibility in applications where fibrous or stringy matter is present in the sludge, providing some impact absorption and reducing the potential for cracking. Conversely, ceramic parts offer superior hardness in the presence of extreme abrasion. Advanced models of submersible sludge pumps will utilize elastomer linings in conjunction with hard metal parts to strike the optimal balance between durability and versatility.

Matching Materials to Sludge Properties:

Material selection should always be apparent in consideration of the sludge properties, such as density, viscosity, chemical aggressiveness, and % solids composition. When material selection is consistent with the sludge pumps’ parameters, it results in longer intervals between overhauls and lower lifecycle costs. For projects requiring short-term deployment, a sludge pump for hire ensures that all required material configurations are available without the need for a capital purchase.

Technical Standards: Wear Ring Clearances and Design Considerations

In addition to material selection, precision in the design of components is critical to ensure the efficiency and reliability of pumps. One of the most important factors to consider is wear ring clearance for centrifugal pump designs.

Normal Working Clearances:

Industry best practices recommend specific diametral clearances depending on the impeller size. Smaller impellers require tighter tolerances, while larger diameters call for incremental increases to prevent metal-to-metal contact. Adhering to these guidelines ensures that pumps maintain hydraulic efficiency without compromising the integrity of their components.

API Standards for Safety and Efficiency:

API standards establish minimum clearance values that strike a balance between energy efficiency and safe operation. Compliance with these standards provides procurement teams with confidence that the sludge pumps under consideration meet globally recognized benchmarks for performance and reliability.

Balancing Tight vs. Loose Tolerances:

Tight clearances improve efficiency by minimizing leakage losses but may increase the risk of contact under thermal expansion or misalignment. Looser clearances extend component life but may slightly reduce efficiency. The challenge lies in balancing these factors to meet the demands of the operating environment. In submersible sludge pump systems, this balance is especially important, as retrieval and service require significant labor and downtime.

Implications for Procurement:

Understanding wear ring design helps decision-makers compare pump technologies more accurately. A sludge pump for hire may provide a valuable opportunity to trial different configurations before committing to a purchase, ensuring the best balance between efficiency, longevity, and maintenance cost. By prioritizing proven design standards, organizations can ensure that their pumps operate reliably even under severe conditions.

Pump Selection Process: A Systematic Approach

Selecting the right equipment for demanding environments requires more than a quick review of specifications. A structured process ensures that sludge pumps are properly matched to application conditions, delivering reliability and efficiency over the long term.

Step 1: Identify Sludge Properties

The first step is to analyze the characteristics of the medium to be pumped. Density, viscosity, solids concentration, and chemical load all affect the stress placed on pump components. High-density slurries or corrosive fluids demand more robust configurations than lighter municipal effluents.

Step 2: Define Hydraulic Requirements

Accurate flow rate and total dynamic head (TDH) calculations ensure the pump will perform efficiently across both normal and peak operating conditions. This helps avoid overloading or underutilization, which can shorten the service life of sludge pumps.

Step 3: Match Pump Type

Different pumps are suited to different sludge conditions. Centrifugal pumps are best suited for high-volume flows, while submersible sludge pumps offer advantages in compact or flooded sites. Progressive cavity pumps may also be used if the sludge is particularly viscous or shear-sensitive.

Step 4: Select Materials for Wetted Parts

Material selection must reflect both the abrasiveness and corrosiveness of the sludge. Options include high-chrome alloys for enhanced abrasion resistance, stainless steels for improved corrosion control, or elastomers and ceramics for specific applications. The choice of material has a direct impact on long-term performance.

Step 5: Confirm Maintenance and Support

Accessibility of wear parts, availability of spares, and manufacturer support are crucial for minimizing downtime. Procurement teams should favor OEMs and suppliers with a strong local presence to ensure continuity of service.

Step 6: Evaluate Lifecycle ROI vs. Upfront Cost

The lowest purchase price does not always equate to the lowest lifecycle cost. Factoring in maintenance frequency, energy efficiency, and expected uptime helps determine the true return on investment. For temporary or urgent requirements, a sludge pump for hire provides immediate access to equipment without the financial commitment of ownership.

Real-World Applications Across Industries

The versatility of sludge pumps makes them indispensable across a wide spectrum of industries, each with unique challenges and requirements.

Mining

In mining environments, sludge pumps are utilized to transfer abrasive tailings and mineral slurries. Their characteristics to endure constant exposure to sharp solids and enable production while reducing downtime make them critical components of a mining operation. Sludge pump designs are deployed in slew sumps and underground locations where there might be limited room for equipment.

Oil & Gas

Energy producers often look to sludge pumps for handling drilling muds, produced water, and other byproducts. Resistance to corrosion is paramount in these environments because chemical exposure will quickly deteriorate standard materials. Rental opportunities, for instance, a sludge pump for hire, provide flexibility for temporary drilling or seasonal demands.

Municipal

Wastewater treatment plants and stormwater systems rely on sludge pumps to move large amounts of fluid containing mixed solids. Again, submersible sludge pumps designs are prevalent due to their ease of installation in limited space and ability to operate fully submerged, which minimizes the footprint of a pump, thus simplifying the system layout.

Defense and Naval

Military and naval initiatives require complete trust and reliability, as the terms “downtime” and “safety” do not coexist. Sludge pumps assist in dewatering, waste management, and emergency pumping. Assurance of wear-resistant materials and proven designs is critical in these situations. For temporary missions or short-term projects, a sludge pump for hire enables quick and easy mobilization without investing a lot of time in purchasing and procurement.

Procurement Insights: Balancing Cost, Durability, and Flexibility

When making procurement decisions, it is crucial to consider the long-term implications of equipment choice beyond the headline purchase price. For organizations operating in demanding environments, sludge pumps must deliver both durability and efficiency to ensure a strong return on investment.

Comparing Vendors and Technologies

Procurement teams should evaluate vendors not only on cost but also on technical specifications, material quality, and proven wear resistance. Pumps engineered with high-chrome alloys, hardened stainless steels, or advanced elastomers demonstrate superior resilience against abrasion and corrosion. A thorough review of these material specs provides clarity on how well a unit will perform over extended duty cycles.

After-Sales Support and Spare Parts Availability

The reliability of sludge pumps depends on the availability of critical spares and responsive service. Choosing suppliers with established after-sales support reduces the risk of extended downtime and ensures maintenance intervals are managed effectively. This factor often outweighs minor differences in initial cost, particularly for industries where uptime directly influences revenue.

Role of Submersible Pumps in Remote and Confined Sites

In situations where space is limited or direct fluid access is required, the submersible sludge pump offers a practical solution. Its compact design allows for direct installation in sumps, tanks, or flooded environments, thereby reducing system complexity. For mining sites, municipal wastewater plants, and naval facilities, this versatility makes submersible sludge pumps a preferred choice.

Ownership vs. Hire Decisions

Not all projects justify the purchase of new equipment. Seasonal workloads, emergencies, or pilot projects may be better served with a sludge pump for hire. This approach allows organizations to access high-performance technology without capital expenditure, while retaining the option to invest once long-term demand is proven. Balancing ownership with rental options gives procurement managers the flexibility to align budgets with operational realities.

Conclusion

The performance and runtime of sludge pumps are directly related to material properties, including resistance to wear, and the process of purchasing them correctly. If durability is made an utmost priority for a pump or pump type, and the purchase/pump choice matches the specific use case, the number of breakdowns should decline. At the same time, service intervals will either increase or remain the same. Likewise, lifecycle costs will be lower.

The ultimate return on investment of a sludge pump is not the lowest purchase price, but rather less downtime, more uptime, and a predictable preventive maintenance service schedule. Plus Pumps AU can assist in that regard with a permanent investment, as well as flexible sludge pump for hire solutions.From mining, municipal, and naval applications, Plus Pumps AU can ensure the proper equipment is matched to the challenge. Please review the full selection of sludge pumps on this site, including advanced submersible sludge pump options. The right selection today will help ensure no surprises in ongoing performance in the future.