Introduction

Abrasive slurry pump technology is purpose-engineered for industries where fluid transfer involves highly abrasive and viscous mixtures, such as those found in mining, dredging, power generation, and mineral processing. In such demanding environments, conventional pumps quickly deteriorate due to excessive wear from solid particles like sand, gravel, and crushed ore. To withstand these harsh conditions, it is built with advanced metallurgy, precision hydraulic design, and specialized sealing systems that reduce erosion and leakage. Components made from high-chrome alloys or elastomer linings ensure exceptional resistance to abrasion and corrosion. By maintaining consistent flow rates and minimizing downtime, the system delivers long-term reliability, improved operational efficiency, and lower overall maintenance costs for heavy-duty applications.

For plant operators and project managers, challenges such as high wear rates, frequent servicing, and energy inefficiencies are common barriers to productivity. Modern abrasive slurry pumps address these issues through precision engineering and efficiency-driven designs that lower lifecycle costs while maximizing reliability.

PlusPumps is recognized as a trusted partner in this space, offering the latest hydraulic systems and anti-abrasive sand slurry pump solutions built for endurance and performance. Each slurry pump and anti-abrasive sand slurry pump in its range is engineered for rugged conditions, ensuring exceptional durability, safety, and long-term operational value across mining, dredging, and industrial applications.

Understanding Abrasive Slurries and Their Impact on Pump Performance

A thick mixture of liquid, usually water, and solid particles, such as sand, gravel, ore fragments, or mineral waste, is called an abrasive slurry. These solid particles are especially hostile to mechanical components because they are frequently angular, hard, and irregular in form. Particle hardness, shape, and concentration have a major impact on wear and tear in slurry systems. Higher concentrations increase the frequency of contact, accelerating the rate of material erosion within the system; harder particles, such as quartz or metal ores, cause deep surface abrasion; sharp-edged particles cut and gouge components.

In real-world industrial settings, abrasive slurries are used in operations such as mine tailings transport, sand-laden dredging, and mineral pipeline transfer systems. Each of these applications exposes critical components, especially the abrasive slurry pump, to extreme mechanical stress and continuous surface impact. In such conditions, conventional equipment fails rapidly, while high-performance abrasive slurry pumps are designed to maintain efficiency and resist degradation.

Erosion, corrosion, and cavitation are the three primary processes that usually cause material degradation in slurry systems. When abrasive particles repeatedly strike rubber or metal surfaces, material is eroded. Chemical interactions between the slurry’s liquid phase and the pump components cause corrosion, which is often exacerbated by high temperatures or acidic conditions. Another harmful component that causes micro-pitting and cracking on metal surfaces is cavitation, which occurs when vapor bubbles suddenly collapse in low-pressure locations. Over time, each of these procedures reduces the system’s efficiency and reliability.

To counter these challenges, advanced abrasive slurry pumps are built with reinforced materials, optimized internal geometries, and replaceable liners that minimize surface damage. PlusPumps integrates these principles into every slurry pump it designs, ensuring stable hydraulic performance and extended operating life even in the harshest applications. Each anti-abrasive sand slurry pump from PlusPumps is further enhanced with corrosion-resistant alloys, precision-cast impellers, and flow-optimized channels, delivering a level of durability and performance that sets new benchmarks in heavy-duty slurry transport. Through superior engineering and materials innovation, PlusPumps’ abrasive slurry pumps provide consistent, efficient operation across industries where wear resistance defines profitability and uptime.

What Makes an Abrasive Slurry Pump Different

The engineering of an abrasive slurry pump is fundamentally different from that of a standard pump. While conventional pumps are designed primarily for clean fluids, a slurry pump must handle mixtures loaded with hard, irregular solids that cause constant erosion and impact. Every part, including the internal geometry and casing, is designed to withstand severe wear from abrasive materials while maintaining steady performance and energy efficiency throughout long operating cycles.

A defining feature of an abrasive slurry pump is its thick-walled casing, which is designed to absorb and withstand continuous particle impact. Wear-resistant materials such as high-chrome metals, industrial-grade rubber, and sophisticated ceramics are used to build these casings, providing remarkable endurance under high pressure and abrasive loads. By using materials specifically selected for hardness and resilience, slurry pumps significantly reduce surface erosion, ensuring longer service intervals and consistent hydraulic performance in high-solid environments.

Increased clearances and flow-optimized shapes are equally crucial. Abrasive particles may move through the system with less turbulence and fouling thanks to these design improvements. The pump maintains a smoother flow profile, increasing overall efficiency and prolonging the life of critical components by reducing internal friction and particle-to-surface collisions. Additionally, by controlling velocity gradients, this design helps prevent localized wear and hot spots that can cause typical systems to fail prematurely.

The addition of modular parts and changeable liners is another fundamental advance. Rubber, polyurethane, or hardened-metal liners in a modern slurry pump can be easily changed without disassembling the entire apparatus. In sectors where equipment uptime directly affects revenue, this modular strategy simplifies maintenance, decreases downtime, and saves overall operating costs.

When assessing lifespan cost and mean time between overhauls (MTBO), the usage of anti-abrasive compounds is equally important. Compared to typical materials, components made from high-alloy metals or premium elastomers can withstand the combined effects of corrosion, cavitation, and abrasion far better. This entails fewer replacements, less frequent service, and more consistent maintenance schedules.

PlusPumps integrates all these design fundamentals into its abrasive slurry pumps and anti-abrasive sand slurry pump range, combining robust materials with precision-engineered hydraulics. Each slurry pump is optimized for durability and operational efficiency, delivering measurable savings through reduced downtime, extended MTBO, and superior wear resistance in even the most aggressive slurry-handling environments.

Types of Abrasive Slurry Pumps Used in Industry

In demanding industries such as mining, dredging, and mineral processing, choosing the right slurry pump configuration is essential to achieving efficiency, durability, and long-term cost control. Each pump type serves a specific operational need, from high-capacity material transport to submersible or high-pressure slurry movement. Understanding these distinctions helps decision-makers select the most suitable abrasive slurry pumps for their process conditions.

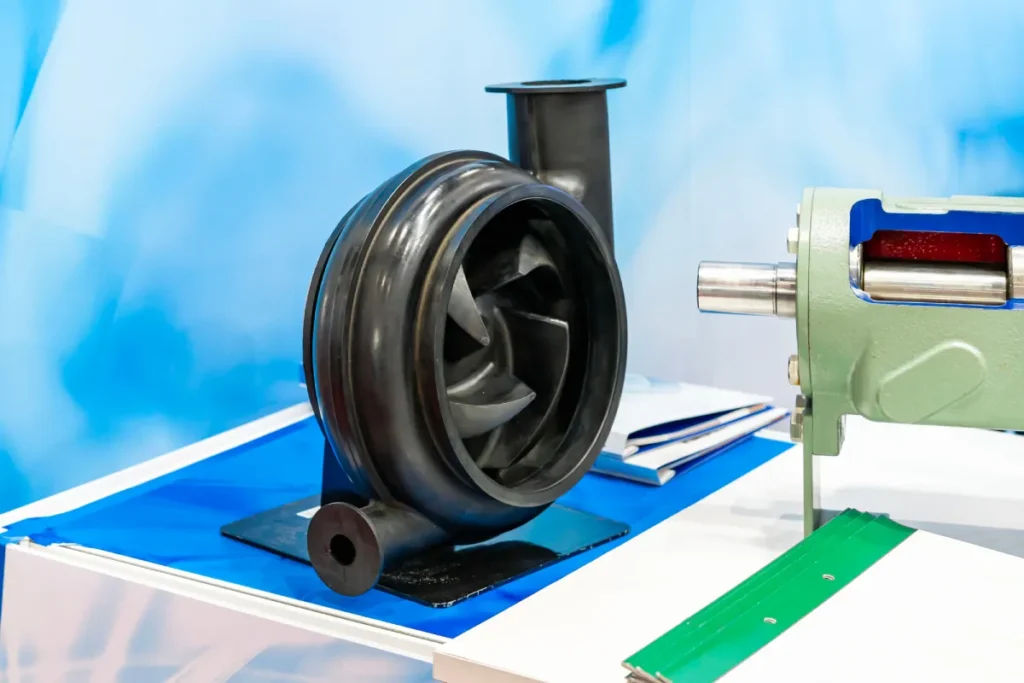

Centrifugal slurry pumps are the most widely used type across mining and mineral processing operations. Acting as the workhorses of the industry, these abrasive slurry pumps are engineered to handle large volumes of dense slurry with consistent flow rates. They are perfect for ore transport, tailings disposal, and mineral recovery circuits because of their heavy-duty impellers and wear-resistant liners, which are optimized for high solids loading and longer operating life.

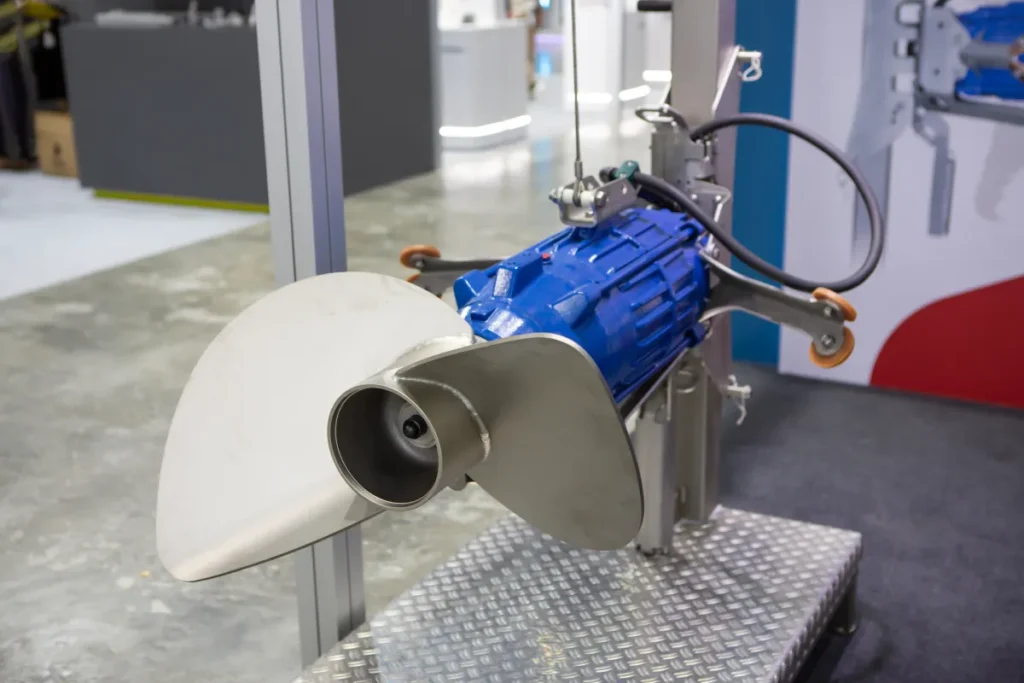

Submersible slurry pumps are designed for applications where the pump must operate fully or partially submerged, such as dredging, sump cleaning, or marine reclamation. Their sealed construction and self-cooling capability make them reliable in environments where heat buildup and accessibility are key challenges. These abrasive slurry pumps ensure efficient operation under high sediment loads, reducing maintenance downtime and improving performance stability in harsh underwater conditions.

Vertical abrasive slurry pumps are perfect for pits, acidic solutions, and intermittent operations where space and fluid exposure are critical considerations. By keeping the drive components above the slurry line, their design shields motors and bearings from abrasive or corrosive damage. Vertical abrasive slurry pumps provide excellent durability and consistent output across varying process demands by maintaining stability under varying flow conditions.

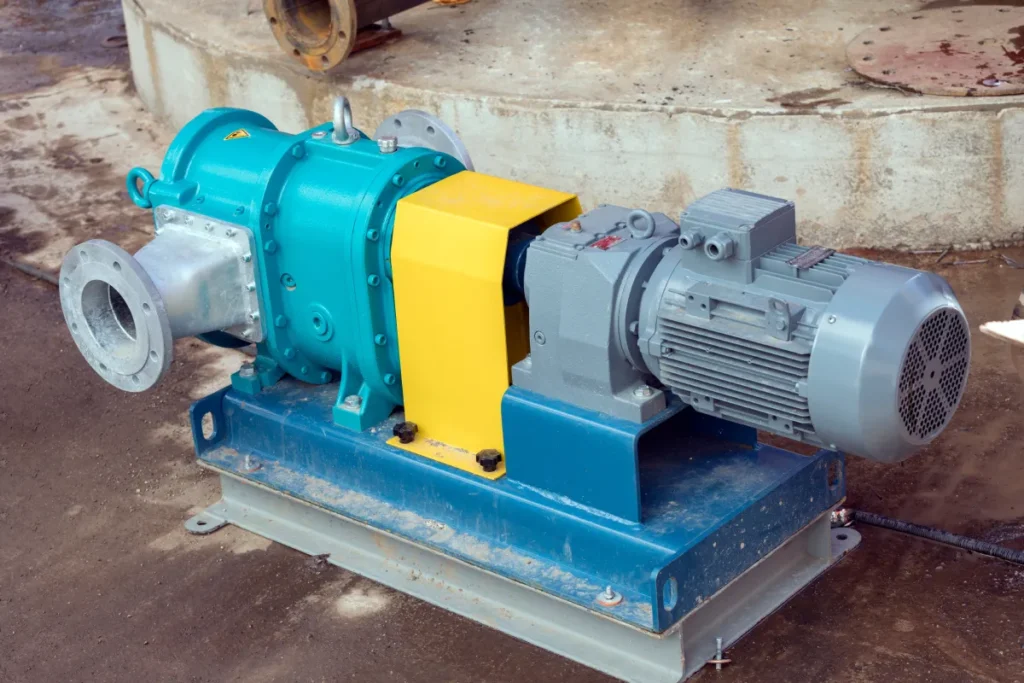

For highly viscous, high-solids, or high-pressure transport systems, positive displacement and specialty pumps, including hydraulic slurry pumps, are preferred. These pumps ensure consistent flow with less pulsation by providing regulated discharge pressure and excellent handling of thick or non-homogeneous slurries.

PlusPumps’ innovative hydraulic designs integrate the proven strength of traditional slurry pump engineering with advanced hydraulic efficiency. Each unit is precision-built to manage extreme abrasive loads while maintaining high energy performance across continuous duty cycles. The company’s anti-abrasive sand slurry pump range reflects this balance between ruggedness and precision, offering tailored solutions for mining, dredging, and industrial sectors that demand reliability in challenging operating environments. With modular construction, wear-resistant alloys, and optimized fluid dynamics, PlusPumps’ abrasive slurry pumps deliver unmatched consistency, durability, and performance where uptime and long-term value matter most.

Engineering for Distance and Durability: Long-Range Slurry Transport

Long-distance transportation of thick, abrasive slurries requires a highly developed system that maintains flow velocity, maintains constant pressure, and reduces energy losses over vast pipeline networks. Each abrasive slurry pump designed for long-distance transportation is tuned to balance mechanical durability and hydraulic performance, ensuring effective material movement with low wear and energy consumption.

The use of multi-stage pressure systems, in which multiple impeller stages cooperate to provide the required discharge head, is a significant advancement in long-distance slurry transport. By reducing mechanical strain and extending operational life, this phased technique enables the slurry pump to maintain constant pressure along the pipeline without overloading individual components. Even when operating over many kilometers, these pumps achieve excellent efficiency and a reliable pressure supply by evenly distributing the burden across stages.

Another crucial component of a high-performance abrasive slurry pump’s design is anti-settling flow control. By keeping the velocity constant, solid particles are prevented from settling in the pipeline, which may otherwise result in obstructions, higher friction losses, and accelerated internal wear. The internal geometry of the pump is meticulously engineered to minimize turbulence and preserve the laminar flow channels, enabling operators to convey high-density materials smoothly and continuously while using the least energy possible.

Additionally, seal protection technologies are essential for improving long-distance dependability. These systems, which frequently include flushing mechanisms or pressured barriers, shield vital sealing and bearing components from direct abrasive contact. By preventing tiny particles from penetrating moving parts, this invention greatly reduces total repair costs and improves mean time between maintenance intervals (MTBM).

The latest slurry pump’s engineering produces quantifiable performance benefits. Because of less frequent maintenance, less energy is used per tonne of slurry moved, and steady hydraulic efficiency over long operating cycles, operators have less downtime.

PlusPumps integrates these advanced design principles into its anti-abrasive sand slurry pump lineup, ensuring each unit combines power, endurance, and precision for heavy-duty slurry transfer. By focusing on energy optimization, superior sealing protection, and stable pressure performance, every PlusPumps slurry pump delivers predictable, long-term reliability in high-pressure, long-distance material transport applications.

Critical Components That Influence Pump Longevity

Within an abrasive slurry pump, the continuous movement of hard, angular particles subjects internal components to extreme wear, making durability and design precision essential. The impeller, volute casing, liners, shaft seals, and bearings are the most wear-prone parts, and their resilience directly determines the reliability and lifecycle of the abrasive slurry pump. Advances in materials engineering and pump design have enabled these components to operate longer, maintain efficiency, and minimize downtime in harsh, high-solidity applications.

As the slurry’s initial point of contact, the impeller imparts energy to the fluid and drives it through the system. Because of the high-velocity impact of abrasive particles, this component experiences substantial attrition in a traditional design. Modern slurry pump impellers mitigate this damage through precision casting and optimized hydraulic geometry that reduces turbulence and impact angles. Additionally, rubber-coated or high-chrome alloy impellers create a resilient surface that absorbs abrasive forces and minimizes pitting. This results in smoother flow, longer operational life, and stable efficiency throughout demanding cycles.

The volute casing and liners of an abrasive slurry pump experience continuous friction as slurry flows through at high pressure. Modern pumps employ modular liners that can be changed one at a time without removing the entire device, thereby increasing service life. These liners serve as sacrificial barriers, preventing erosion of the pump casing. They are composed of sophisticated ceramics, wear-resistant rubber, or strengthened metal alloys. This modular strategy lowers operating expenses and maintenance time while significantly improving durability.

Shaft seals and bearings are equally vulnerable in abrasive slurry pumps, as fine particles can infiltrate and degrade these precision components. Current designs include pressure-flush mechanisms that shield seals from slurry exposure, and multi-stage sealing systems to avoid it. Lubricated enclosures and labyrinth seals shield bearings from contaminants and minimize heat production. Even under heavy-duty use, these advancements guarantee reliable performance, smoother operation, and fewer mechanical failures.

PlusPumps integrates these advanced design principles across its product range, particularly in its anti-abrasive sand slurry pump line. Each abrasive slurry pump is engineered with optimized flow paths, heavy-duty materials, and strategically reinforced high-wear zones to withstand intense mechanical stress. The company’s proprietary use of hardened alloys, elastomer linings, and modular assemblies ensures unmatched longevity and reliability. Every abrasive slurry pump from PlusPumps is designed to deliver superior wear resistance, higher mean time between overhauls (MTBO), and reduced maintenance intervals.

Engineered for industrial resilience, PlusPumps’ anti-abrasive sand slurry pump technology sets the benchmark for endurance in environments where abrasive forces are relentless. Through precision craftsmanship and advanced materials, each slurry pump provides predictable performance and extended service life, making it a proven solution for industries that demand uncompromising durability.

Building Systems That Last with PlusPumps

In businesses that require continuous performance under harsh conditions, the slurry pump remains a key component of reliability. Every abrasive slurry pump is designed to handle high-density abrasive materials and deliver consistent performance in applications where strength, durability, and efficiency are critical.

PlusPumps has built a strong reputation for delivering advanced hydraulic and anti-abrasive sand slurry pump solutions that combine endurance, safety, and proven ROI. Each abrasive slurry pump in its range is engineered with precision materials and optimized hydraulics to minimize wear, reduce downtime, and enhance long-term reliability.

From mining and dredging to heavy industrial use, PlusPumps’ anti-abrasive sand slurry pump systems deliver superior performance in challenging environments. With a focus on durability and energy efficiency, every slurry pump is designed to provide stable output, predictable maintenance intervals, and lasting value.Discover how PlusPumps can help you optimize your slurry transport and extend equipment life with robust, high-performance abrasive slurry pump and anti-abrasive sand slurry pump technology built for the world’s toughest industrial operations.