Traditional dredging has long been associated with labor-intensive operations, hazardous working conditions, and limited access to difficult or dangerous environments. From industrial sludge ponds to remote lagoons, deploying a crew and equipment often poses logistical and safety challenges. The need for more efficient, precise, and safer dredging operations has fueled the demand for innovation in the industry.

Enter the remote operated dredge—a game-changing advancement in dredging technology. With the integration of smart sensors, GPS navigation, real-time monitoring, and wireless control, these systems are designed to perform sediment removal without requiring operators to be physically on the water. A remote control dredging system not only enhances worker safety but also boosts operational efficiency, particularly in restricted-access or high-risk environments.

This shift toward automation is part of a broader trend that embraces digital transformation and sustainable practices across various industries. Companies are increasingly adopting remote dredging solutions to reduce costs, improve environmental compliance, and maximize uptime.

In this blog, we’ll explore how a remote operated dredge works, highlight key features and benefits, and examine where these systems are most effectively used. We’ll also look ahead at future trends shaping this technology and offer guidance on selecting the right remote control dredging system for your next project.

What is a Remote Operated Dredge?

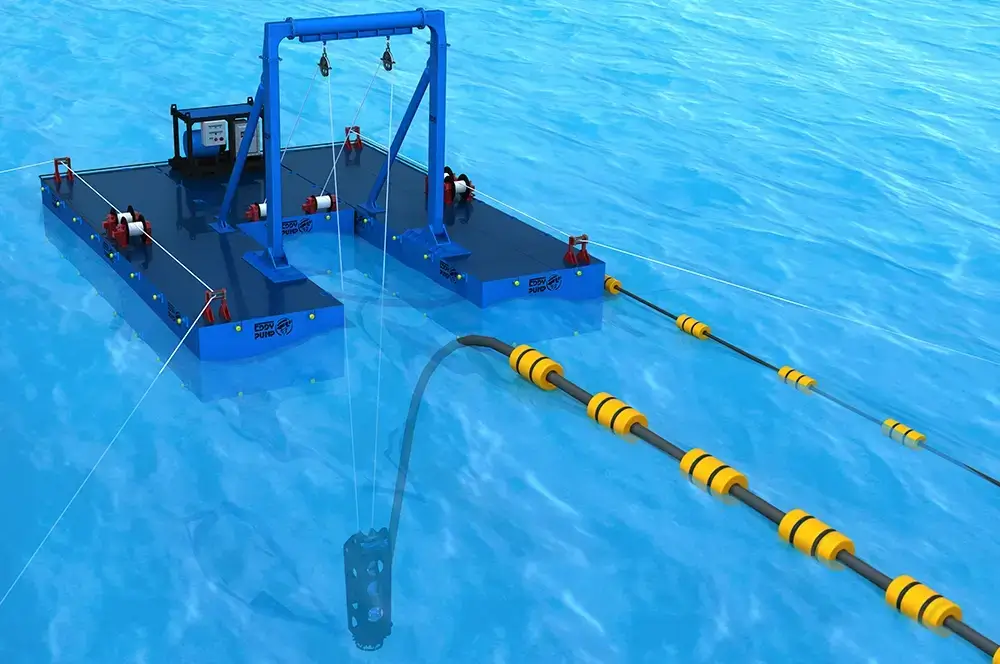

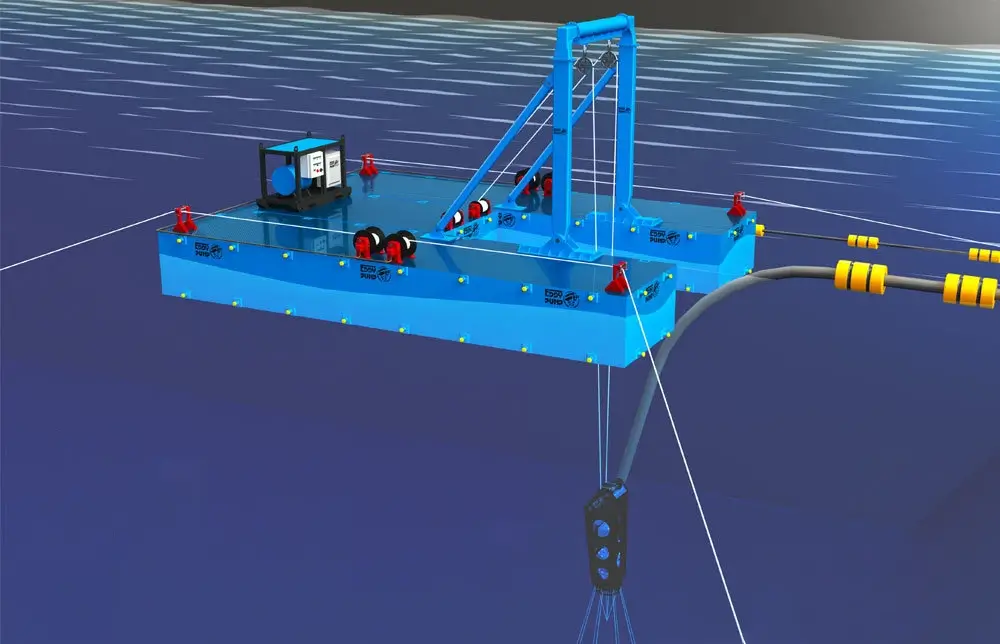

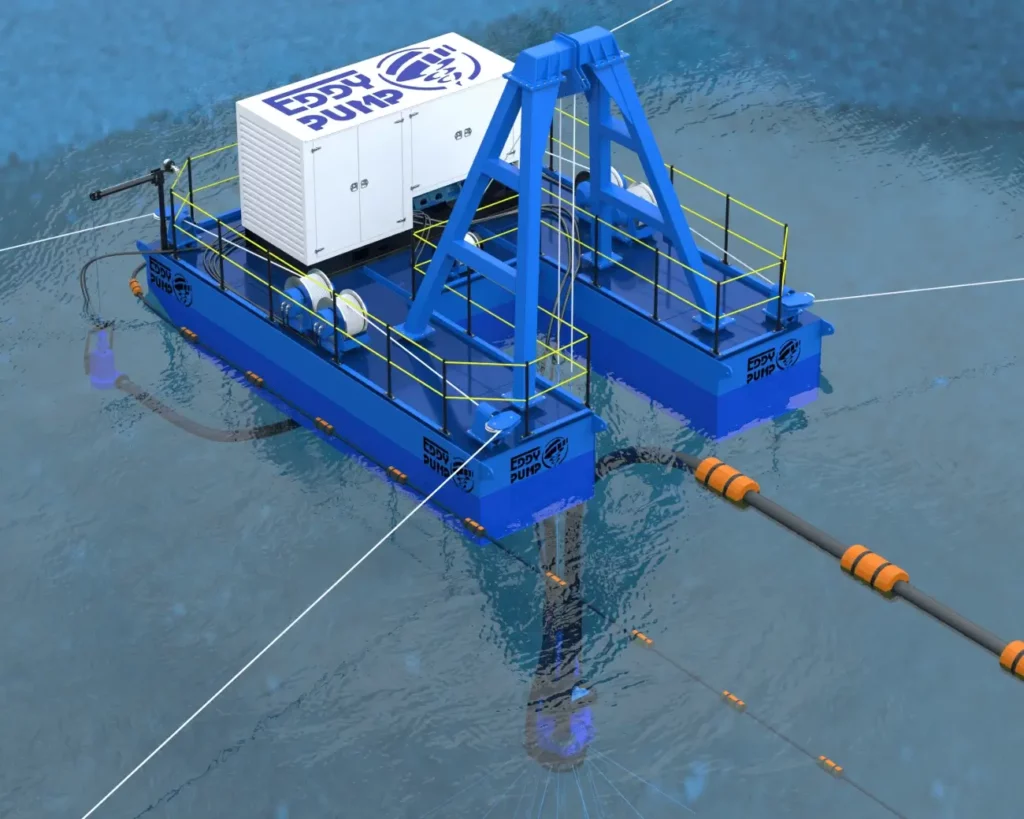

A remote operated dredge is a modern dredging system designed to remove sediment, sludge, and debris from water bodies without the need for onboard human operators. Unlike traditional dredgers, which require a full crew to operate the machinery directly on the vessel, a remote operated dredge is controlled from a safe distance using advanced communication and control technologies. This not only enhances worker safety but also allows for greater precision, operational efficiency, and access to locations that might otherwise be too dangerous or remote for manned equipment.

The operation of a remote operated dredge is made possible through the integration of real-time sensors, GPS positioning systems, HD cameras, and telemetry modules. These components work together to transmit live operational data to a land-based or mobile control station. The operator can then monitor dredging progress, adjust dredge head depth, and manage pump flow remotely, ensuring accuracy and minimizing disruption to surrounding environments.

A typical remote control dredging system consists of several key components:

- Control Station: A user-friendly interface that allows operators to control and monitor the dredge’s performance in real time.

- Power Pack: Houses the hydraulic or electric systems that drive the dredge’s pump and movement.

- Dredge Head and Pump Unit: The core components responsible for cutting, agitating, and transporting sediment through discharge hoses.

Remote dredging solutions are especially valuable in areas such as wastewater treatment lagoons, mining ponds, or hazardous industrial sites, where traditional manned dredging poses safety or access challenges. These systems reduce the need for large crews and lower the risk of exposure to toxic or unstable conditions.

As more industries adopt automation, the demand for remote dredging solutions continues to grow. A well-designed remote control dredging system offers not only improved safety and reduced labor costs but also higher precision and data-driven operation, making the remote operated dredge an essential tool in the future of sediment management.

Key Features and Technological Advantages

The remote operated dredge is redefining the way dredging is performed, offering a range of advanced features that deliver superior control, safety, and performance across a variety of environments. With advancements in technology, these systems are no longer limited to specialized applications—they are becoming mainstream solutions for efficient sediment removal.

One of the standout features of a remote operated dredge is the choice between wireless and tethered control systems. Wireless setups allow for complete freedom of movement and operation from virtually any location, while tethered systems ensure constant communication in environments with potential signal interference. Both configurations offer dependable control, allowing operators to manage dredging activities without setting foot on the water.

Real-time monitoring is another core benefit. Using onboard sensors, GPS, and video feeds, operators can precisely guide dredge heads, maintain target depths, and avoid obstacles. This precision not only boosts productivity but also minimizes environmental impact—an essential consideration in regulated or sensitive sites.

Reduced crew requirements are a major advantage, especially in hazardous or remote locations. A single technician can operate a remote control dredging system from a safe distance, significantly lowering the risk of injury and cutting down labor costs.

Additional technological benefits include built-in data logging and remote diagnostics. Operators can review historical performance, track sediment removal volumes, and receive alerts for equipment malfunctions. This data-driven insight supports smarter maintenance planning and improved operational efficiency over time.

Scalability is another strength of the remote operated dredge. These systems are adaptable to both small-scale applications, such as pond and canal maintenance, and large-scale industrial basins or mining operations. This versatility makes remote dredging solutions a valuable asset across a wide range of industries.

Incorporating a remote control dredging system into your operations not only improves productivity but also aligns with modern safety and sustainability goals. With features designed for both control and convenience, remote dredging solutions represent a significant leap forward in sediment management technology.

Applications and Use Cases

The versatility of a remote operated dredge makes it an ideal solution across a wide spectrum of industries and environments where traditional dredging methods may fall short due to safety, access, or operational constraints. These systems are designed to deliver efficient sediment removal with minimal disruption, making them highly effective in several key applications.

Industrial Wastewater Lagoons and Settling Ponds

Facilities that manage wastewater or chemical byproducts often rely on large lagoons and settling basins to handle suspended solids. A remote operated dredge allows plant operators to maintain sediment levels without exposing personnel to hazardous materials or disrupting plant operations. Using a remote control dredging system in these environments ensures safe, continuous operation with real-time monitoring and precision.

Mining Tailings and Sludge Management

In mining operations, managing tailings and thick sludge is a constant challenge. A remote operated dredge can be deployed in tailings ponds to recover valuable materials or to maintain pond capacity. These units operate without the need for personnel to navigate unstable or toxic surfaces, reducing liability and improving safety protocols.

Flood Control Basins and Stormwater Retention Ponds

Municipal and regional authorities use stormwater ponds to manage runoff during heavy rainfall. Sediment buildup reduces capacity and increases flood risks. A remote operated dredge can clear these basins efficiently while operating in restricted or difficult-to-access areas. These dredges are particularly useful for routine maintenance without major construction or excavation work.

Remote, Hazardous, or Restricted-Access Locations

From nuclear facility retention ponds to high-salinity lagoons, certain sites are simply too dangerous for manual intervention. Remote dredging solutions provide a safe and effective alternative, allowing sediment removal in places where traditional crews cannot operate safely.

Aquaculture and Canal Maintenance

In aquaculture settings, maintaining clean water is vital for fish health and productivity. A remote control dredging system helps remove excess organic material and maintain water circulation. Similarly, in canals or narrow waterways, remote dredging solutions offer the flexibility and control needed to operate in confined spaces with minimal disturbance.

These use cases highlight the practical advantages of integrating a remote operated dredge into diverse operations, ensuring both safety and operational efficiency.

Benefits Over Traditional Dredging Methods

The transition from traditional dredging practices to modern remote solutions has introduced significant advantages in terms of safety, efficiency, environmental protection, and cost-effectiveness. A remote operated dredge offers a smarter, more sustainable approach to sediment removal, especially in environments where conventional dredging presents operational challenges.

Enhanced Safety

One of the most compelling benefits of using a remote operated dredge is the reduction in on-site personnel exposure. Traditional dredging often requires operators to work on floating platforms or in close proximity to deep, unstable, or hazardous environments. In contrast, a remote control dredging system allows operators to manage all dredging functions from a safe, land-based control station, drastically minimizing the risk of injury, chemical exposure, or accidents.

Greater Efficiency

Remote operated dredges enable extended operational hours without fatigue-related slowdowns. Unlike manual crews that are limited by shift schedules and safety breaks, these systems can work continuously, resulting in faster project completion. Reduced labor needs also lower overhead costs, making operations leaner and more streamlined.

Environmental Precision

Remote dredging solutions offer more precise control over dredge head movement and sediment extraction. With real-time monitoring and programmable depth controls, these systems minimize turbidity, prevent unnecessary disturbance to aquatic life, and maintain water clarity during operation. This level of control is especially valuable in regulated environments where environmental compliance is a priority.

Long-Term Cost Savings

Though initial investment in a remote operated dredge may be higher than renting conventional equipment, the long-term cost benefits are substantial. Lower labor requirements, fewer safety incidents, and reduced equipment wear translate to significant savings over time. Maintenance is also easier with remote diagnostics, allowing early identification of potential issues before they escalate.

Adaptability to Diverse Conditions

A remote control dredging system is highly adaptable, working efficiently in various settings—from confined retention basins to expansive mining ponds. This versatility eliminates the need to maintain a fleet of specialized dredges for different environments, further reducing capital expenditures.

In summary, remote dredging solutions are redefining industry standards by enhancing safety, optimizing efficiency, protecting ecosystems, and delivering long-term value—making the remote operated dredge an essential tool for forward-thinking operations.

Future Trends in Remote Dredging Solutions

As the dredging industry continues to evolve, the future of remote dredging solutions is being shaped by advancements in automation, connectivity, and sustainability. The remote operated dredge is no longer just a safer and more efficient alternative—it’s becoming a high-tech tool driven by intelligent systems and data integration.

AI and Machine Learning Integration

Emerging technologies are enabling remote operated dredge systems to make autonomous adjustments during operation. By leveraging AI and machine learning, these systems can optimize dredging routes, adapt to sediment conditions in real time, and reduce fuel and energy consumption without operator intervention. This capability not only increases efficiency but also ensures more consistent and accurate results.

Cloud-Based Control and Data Management

Future-ready remote control dredging systems are moving toward cloud-based platforms. These allow operators to access live operational data, historical performance metrics, and system diagnostics from anywhere in the world. Cloud integration enhances collaboration between teams, simplifies remote troubleshooting, and supports predictive maintenance, helping to avoid costly downtime.

Sustainable Energy Solutions

With a growing focus on environmental responsibility, many remote dredging solutions are incorporating electric drive systems and solar-assisted power units. These sustainable energy sources reduce carbon emissions and operating costs, making the remote operated dredge an eco-friendly alternative to diesel-powered machines.

GIS Mapping and Environmental Compliance Tools

Advanced remote control dredging system platforms are beginning to integrate with GIS (Geographic Information System) mapping. This allows operators to visualize dredging areas, track progress with geospatial accuracy, and automatically document environmental impact. The ability to align operations with regulatory requirements in real time helps companies stay compliant and avoid fines or delays.

Looking ahead, the combination of smart technology and sustainability is expected to redefine how sediment removal is performed. Remote dredging solutions will continue to evolve into fully autonomous, low-impact systems that deliver both performance and environmental stewardship. For industries aiming to future-proof their operations, investing in a remote operated dredge today sets the stage for long-term success and innovation tomorrow.

Conclusion

The remote operated dredge represents the next generation of dredging technology—combining precision, safety, and efficiency in a single, powerful system. With its ability to minimize human exposure, operate in hard-to-reach or hazardous environments, and deliver data-driven performance, this innovative equipment is reshaping how sediment management is approached across industries.

As businesses face increasing demands for operational safety, environmental compliance, and cost-efficiency, remote dredging solutions offer a smart, scalable path forward. From wastewater lagoons to stormwater ponds and mining tailings, these systems deliver consistent results while reducing risk and labor requirements.

If you’re considering upgrading your dredging operations or looking to implement new technologies, our team is here to help. We offer expert guidance, product comparisons, and hands-on equipment demos to ensure you find the right fit for your project needs. Contact us today to explore how a remote operated dredge can transform your approach to sediment removal.