Hydraulic slurry pump systems are redefining how industries move the unmovable. In mining, dredging, oil and gas, and heavy construction, where thick slurries and abrasive mixtures push machinery to its limits, these pumps deliver the torque and durability required for nonstop performance. They replace high-maintenance, inefficient methods with controlled, continuous material flow—whether transporting tailings or removing sediment from riverbeds.

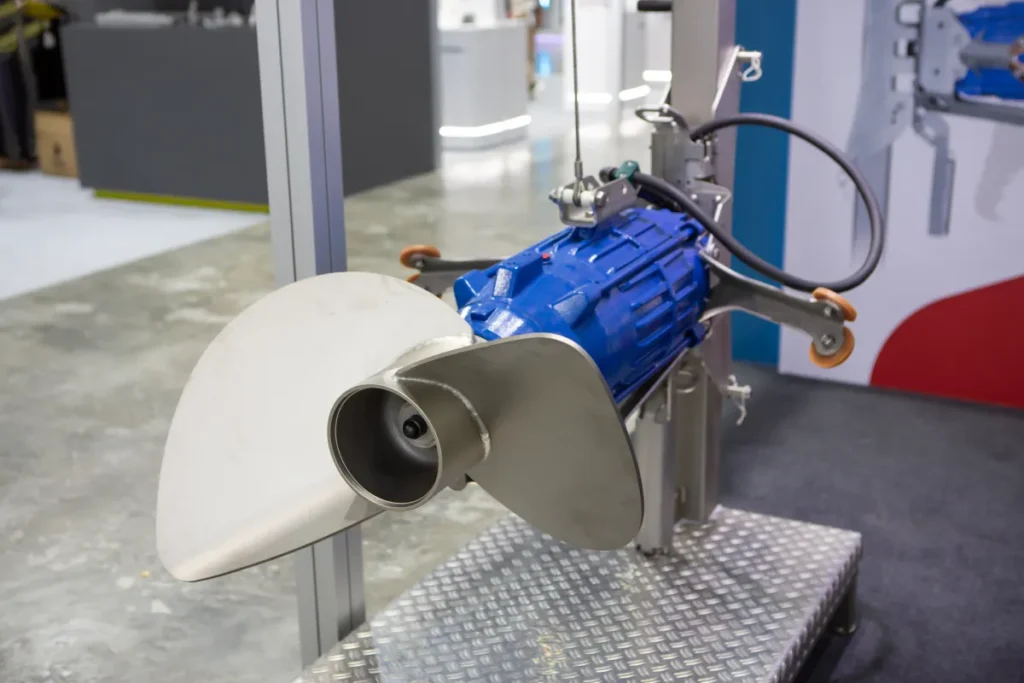

Powered by hydraulics instead of electricity, these pumps maintain consistent output in harsh environments. The hydraulic submersible slurry pump operates efficiently when fully submerged, making it ideal for excavator attachments, dredging platforms, and remote transport. When paired with dredge slurry pump hydraulic systems, they move material with minimal clogging or wear.

Built for heavy-duty use, hydraulic submersible and dredge slurry pump configurations reduce downtime, handle high solids content, and extend service life. Backed by decades of field expertise, Plus Pumps AU supplies these systems to industrial and government sectors across Australia, trusted for reliability and proven performance in demanding slurry operations.

Benefit #1: Superior Solids Handling Capability

In industries where mud, sand, gravel, and debris are constant factors, the hydraulic slurry pump delivers standout solids-handling performance. Unlike conventional centrifugal units, it is engineered to move abrasive and mixed materials without clogging or losing flow efficiency. Its high-torque hydraulic drive provides steady suction and discharge power, allowing dense slurries to move smoothly through the system.

A major advantage comes from the impeller design and streamlined flow path, which reduces turbulence and blockage. This ensures consistent throughput when handling coarse materials in mining, construction, and dredging operations. The hydraulic submersible slurry pump enhances this further through submerged operation, accessing sediment directly and reducing reliance on auxiliary suction systems. When deployed as part of a dredge slurry pump hydraulic setup, it enables efficient movement of heavy solids from ponds, lagoons, and riverbeds with minimal interruption.

These capabilities also support tailings ponds and dewatering pits where high solids demand continuous-duty output. By minimizing wear and reducing downtime, the hydraulic slurry pump helps maintain productivity in sediment removal, reclamation, and marine dredging applications.

Benefit #2: Enhanced Durability and Wear Resistance

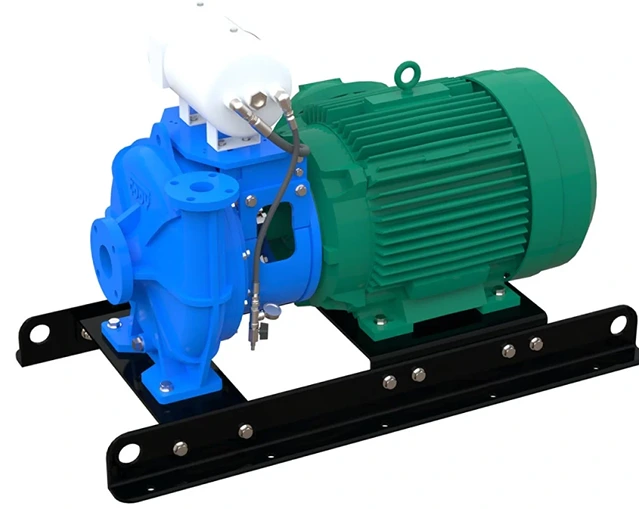

Durability is one of the most valuable advantages of the hydraulic slurry pump, especially in sectors that handle abrasive, corrosive, or high-viscosity materials. Built with reinforced impellers, heavy-duty liners, and wear-resistant alloys, these pumps are engineered to operate in conditions that rapidly wear down conventional systems.

In mining, coastal dredging, and industrial wastewater applications, the hydraulic submersible slurry pump maintains consistent performance under continuous stress. Its construction resists erosion from sand, gravel, and sediment while preserving hydraulic efficiency across long duty cycles. When integrated into a dredge slurry pump hydraulic setup, the system delivers extended service life with fewer disruptions and lower maintenance costs.

Advanced metallurgy and protective coatings further reduce cavitation, corrosion, and mechanical strain. Whether deployed as a standalone unit or as part of a broader pumping assembly, the hydraulic slurry pump offers measurable cost benefits by lengthening equipment lifespan and minimizing component replacement.

In high-demand environments where downtime directly impacts productivity, these hydraulic configurations provide the resilience required to keep critical operations running reliably and efficiently.

Benefit #3: High Power Output with Compact Design

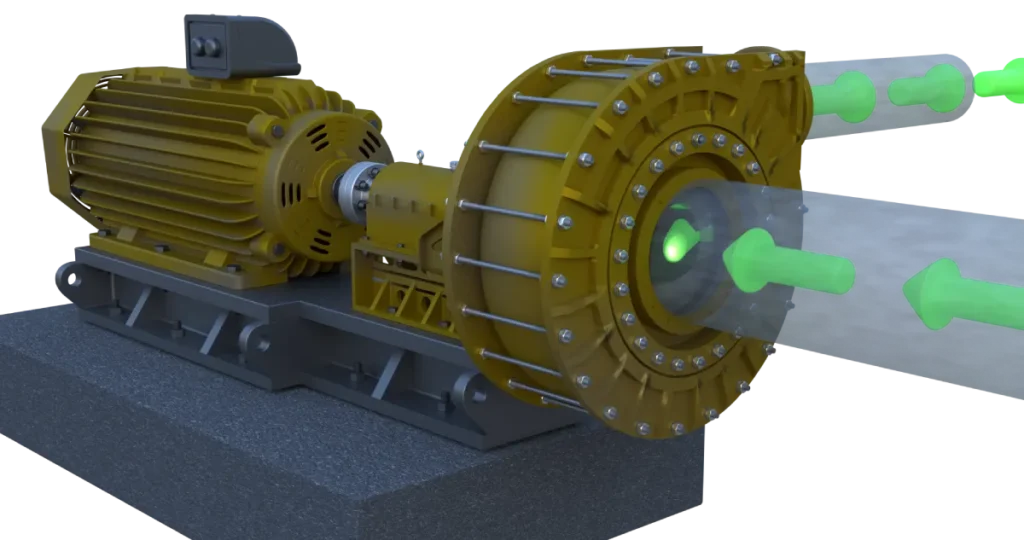

One of the defining strengths of the hydraulic slurry pump is its ability to deliver substantial power from a compact, lightweight system. With a high power-to-weight ratio, the hydraulic drive generates strong torque and consistent pressure without oversized motors or complex assemblies. This makes it ideal for operations requiring mobility, durability, and high output in restricted spaces.

Its compact form accelerates deployment and improves safety in confined dredging zones, remote mining areas, and tight construction sites. The hydraulic submersible slurry pump excels in these environments thanks to its efficient hydraulic transmission and small footprint, integrating seamlessly with excavators, barges, and amphibious platforms. This adaptability reduces logistical challenges and helps maintain steady production in demanding conditions.

A leading example is the use of excavator-mounted dredge slurry pump hydraulic systems. By utilising the excavator’s existing hydraulic power, operators gain high solids-handling capability without auxiliary engines or electrical hookups. The hydraulic submersible slurry pump supports deeper suction and sustained flow performance while efficiently transferring energy in sediments and shallow water.

These advantages enable contractors and industrial operators to deploy the hydraulic slurry pump effectively in situations where space, terrain, or infrastructure constraints make traditional pumping systems impractical.

Benefit #4: Precise Flow and Speed Control

In operations where precision is essential, control over flow rate and pump speed directly impacts performance, safety, and compliance. The hydraulic slurry pump delivers this control through its hydraulic drive, allowing operators to regulate output without compromising pressure or torque.

In confined dredging zones, remote mining locations, and tight construction environments, the hydraulic submersible slurry pump offers a compact, adaptable design that integrates easily with excavators, barges, and amphibious platforms. Its hydraulic transmission enables stable flow and accurate speed control, preventing over-pumping and reducing sediment disturbance during trenching, canal maintenance, or environmental dredging.

When paired with dredge slurry pump hydraulic systems, operators benefit from enhanced precision through automated feedback and real-time adjustment. Remote monitoring and digital controls allow output changes, performance tracking, and rapid response to site conditions. This level of control helps minimise energy use, maintain consistent discharge, and improve operational safety across dredging, mining, and infrastructure projects.

Benefit #5: Minimal Downtime and Maintenance Requirements

A major strength of the hydraulic slurry pump is its low-maintenance design, which reduces system failures and keeps operations running without interruption. With fewer electrical components, seals, and moving parts than traditional pump setups, it eliminates many of the weak points that typically cause breakdowns in abrasive or high-demand environments.

Modular construction makes routine servicing straightforward. Liners, impellers, and casings can be accessed and replaced quickly on-site, avoiding extended shutdowns. The hydraulic submersible slurry pump enhances this further—its sealed hydraulic system is resistant to moisture, corrosion, and electrical faults, making it dependable in wet or chemically aggressive conditions.

When integrated into a dredge slurry pump hydraulic arrangement, the system delivers consistent performance with minimal intervention. Reduced downtime, fewer replacement parts, and extended service intervals translate into measurable cost savings across mining, oil and gas, and dredging operations. The hydraulic slurry pump supports continuous-duty performance while avoiding the complexity and maintenance burden of electric-driven alternatives.

Benefit #6: Versatility Across Heavy-Duty Applications

The hydraulic slurry pump is one of the most adaptable pumping solutions used across modern industry. Its ability to handle dense slurries, sediment-heavy fluids, and abrasive mixtures makes it effective in mining, construction, oil and gas, municipal works, and marine dredging. Designed for high performance in harsh conditions, it maintains efficiency while adapting to different operational environments.

A major advantage is its ability to function in both fully and partially submerged setups. This eliminates the need for lengthy suction lines or complex priming systems. The hydraulic submersible slurry pump performs reliably in lagoons, pits, tailings ponds, and underwater excavation areas, delivering steady solids movement and consistent flow.

Compatibility with multiple hydraulic power sources further broadens its application. Excavator power packs, skid-mounted units, and standalone hydraulic systems can all support these pumps. When configured within a dredge slurry pump hydraulic system, they can be fitted onto barges, amphibious platforms, or floating pontoons to suit diverse job sites.

This flexibility enables efficient operation in tailings recovery, flood management, sediment removal, marine construction, and reclamation works. The hydraulic submersible slurry pump and dredge slurry pump hydraulic combinations allow easy adaptation to changing terrain, water levels, and material types.

By combining modular engineering with high power density, the hydraulic slurry pump delivers dependable performance on land and offshore. It supports rapid deployment, simplified setup, and long service life across demanding sectors where reliability and application range are critical..

Benefit #7: Energy Efficiency and Lower Operating Costs

Energy performance is a critical factor in large-scale material handling, and the hydraulic slurry pump is engineered to deliver high output with minimal wasted energy. Unlike electric-driven systems that lose efficiency through power conversion and transmission, hydraulic drives transfer energy directly and mechanically. This results in smoother torque delivery, consistent pressure, and efficient pumping of viscous or abrasive slurries.

In long-distance transport, the hydraulic slurry pump maintains stable flow with reduced friction loss across extended discharge lines. This is particularly valuable in dredging and mining operations where material must be pumped over challenging distances. Its compact hydraulic design avoids the inefficiencies common with fluctuating electrical loads and oversized motors.

Lower energy demand translates into measurable operating savings. Reduced fuel use, extended maintenance intervals, and fewer replacement parts help control lifecycle costs in both stationary and mobile configurations. The hydraulic submersible slurry pump enhances efficiency by utilizing existing hydraulic systems, thereby eliminating the need for external electrical infrastructure.

When integrated with a dredge slurry pump hydraulic setup, operators gain a streamlined system that optimizes power transfer while cutting unnecessary fuel and equipment overhead. For industries prioritizing cost control and sustainability, the hydraulic slurry pump offers a dependable, energy-conscious solution.

Benefit #8: Safe Operation in Hazardous Environments

Safety is a critical factor in dredging, mining, energy production, and industrial waste management. The hydraulic slurry pump offers a major advantage in these settings by eliminating the electrical hazards associated with conventional pump systems. With no need for live electrical components near water, fuel, or volatile materials, the risk of sparking, overheating, or short-circuiting is significantly reduced.

In environments such as marine zones, refineries, chemical processing sites, and contaminated waterways, dredge slurry pump hydraulic systems provide a safer alternative to electrically powered units. Their fully hydraulic design supports submerged and semi-submerged use without compromising reliability or compliance.

Remote and automated control further improves protection by allowing operators to adjust speed, flow, and pressure from a safe distance. Early monitoring of temperature, pressure, or flow irregularities helps identify potential issues before they escalate.

The hydraulic submersible slurry pump is especially effective in underwater and confined-space applications where electrical systems may fail or pose a danger. When combined with a dredge slurry pump hydraulic arrangement, it delivers stable operation and precise control in challenging environments.

Overall, the hydraulic slurry pump provides an inherently safer solution for high-risk worksites, reducing exposure to hazards while meeting stringent operational standards.

Benefit #9: Continuous Operation in Extreme Conditions

The hydraulic slurry pump is engineered for applications where uninterrupted performance is critical. Built for extended duty cycles, it maintains consistent slurry movement even in high-temperature, high-pressure, or high-solids environments. This reliability is especially valuable in mining, large-scale dredging, marine construction, and emergency response, where operational delays can lead to significant costs and safety risks.

Unlike electric-powered units that may overheat or lose efficiency under heavy load, the hydraulic submersible slurry pump uses a hydraulic drive system that transfers power efficiently and dissipates heat effectively. Reinforced impellers and abrasion-resistant components help it withstand continuous exposure to dense materials and abrasive slurries.

In flood remediation, tailings removal, or coastal restoration, these pumps operate underwater and handle debris-laden material without frequent shutdowns. When configured within a dredge slurry pump hydraulic system, they deliver stable discharge and sustained flow, even in remote or high-impact locations.

This combination of strength, heat management, and solids-handling capability allows the equipment to operate for long durations with minimal performance loss, meeting the demands of both planned projects and urgent field conditions.

Benefit #10: Higher ROI Through Lifecycle Value

Beyond performance, the hydraulic slurry pump delivers clear financial advantages over its service life. Its efficiency, low maintenance needs, and long-term durability reduce total ownership costs. With fewer breakdowns and less frequent component replacement, operators maintain workflow continuity and achieve stronger long-term returns than with conventional pump systems.

In heavy-duty applications, lifecycle assessments consistently show better value compared to electric or centrifugal pumps. The hydraulic drive reduces stress on core components, resulting in fewer failures and lower repair costs. Its versatility across dredging, dewatering, and slurry transport further extends its operational lifespan and return on capital investment.

Modern systems also support predictive maintenance and real-time monitoring. Sensors and performance tracking help detect wear early, allowing servicing before failures occur. This proactive approach improves reliability, prevents costly downtime, and supports consistent output.

By optimising energy use, maintenance schedules, and uptime, the hydraulic slurry pump delivers both operational strength and long-term economic advantage across demanding industrial environments.

Choosing the Right Hydraulic Slurry Pump for Your Project

Selecting the correct system is essential for performance and ROI. Key considerations include flow rate, head pressure, slurry density, particle size, viscosity, and site conditions such as operating depth, fluid makeup, and available hydraulic power.

Proper power matching is critical to maintain torque and avoid performance loss. The hydraulic submersible slurry pump performs best when paired with appropriately sized hydraulic circuits or excavator systems, ensuring efficient energy transfer and reduced component strain. Likewise, dredge slurry pump hydraulic setups must be aligned with discharge distance, depth, and sediment characteristics to achieve the required output.

Plus Pumps AU engineers each hydraulic slurry pump solution to project conditions and operational goals. The team advises on sizing, power configuration, and performance planning for applications such as tailings transport, marine dredging, and dewatering. Their customised systems prioritise durability, efficiency, and reliability across demanding worksites.

Empowering Heavy Industries with Reliable Hydraulic Pumping Solutions

From mining and marine dredging to construction and municipal works, the hydraulic slurry pump has become a benchmark for heavy-duty material transport. Its durability, efficiency, safety performance, and long-term ROI make it a dependable choice for environments where reliability is non-negotiable.

Built to manage abrasive, viscous, and solids-heavy slurries, the hydraulic slurry pump delivers consistent output where conventional systems struggle. The hydraulic drive offers precise control, extended service life, and reduced maintenance, helping operators maximise uptime while lowering overall operating costs. Its capability to perform in submerged or hazardous conditions also supports safer and more compliant operations.

Plus Pumps AU integrates advanced hydraulic engineering with site-specific requirements to deliver fully configured solutions. Whether the objective is dredging, dewatering, or sediment transport, the company designs systems focused on performance, longevity, and measurable returns.Contact Plus Pumps AU to explore hydraulic pumping systems built to handle demanding conditions with confidence and efficiency.