Slurry pumps are essential equipment in industries where transporting fluids laden with solids is a daily operation. These pumps are specifically engineered to handle abrasive, viscous, and highly concentrated slurries—materials that would quickly wear down or clog standard pumps. From mining and dredging to wastewater treatment and tunneling, slurry pumps ensure that heavy materials are moved efficiently through pipelines without system failures or costly downtime.

In high-demand environments, efficiency and reliability are non-negotiable. Selecting the right pump for the application isn’t just a technical decision—it directly affects productivity, energy use, and equipment lifespan. That’s why choosing the correct configuration, flow capacity, and wear-resistant materials is crucial. In scenarios where capital investment is limited or short-term solutions are needed, many companies turn to slurry pump rental options for immediate and cost-effective deployment.

This blog will explore the vital role of slurry pumps in material handling, the industrial applications that rely on them, and how they boost operational efficiency. We’ll also examine when slurry pump rental makes strategic sense and highlight the value of working with trusted slurry pump suppliers. Whether you’re managing a full-scale operation or a temporary project, understanding how to source from the right slurry pump suppliers is key to maximizing performance and minimizing risk.

What Are Slurry Pumps?

Slurry pumps are a specialized category of industrial pumps designed to transport mixtures of liquid and solid particles, commonly referred to as “slurries.” These slurries are typically abrasive, viscous, and often corrosive, making slurry pumps essential for the tough operating conditions found in industries such as mining, dredging, tunneling, and wastewater treatment. The primary function of a slurry pump is to provide the necessary flow and pressure to move dense slurries through a pipeline system without clogging or suffering premature wear.

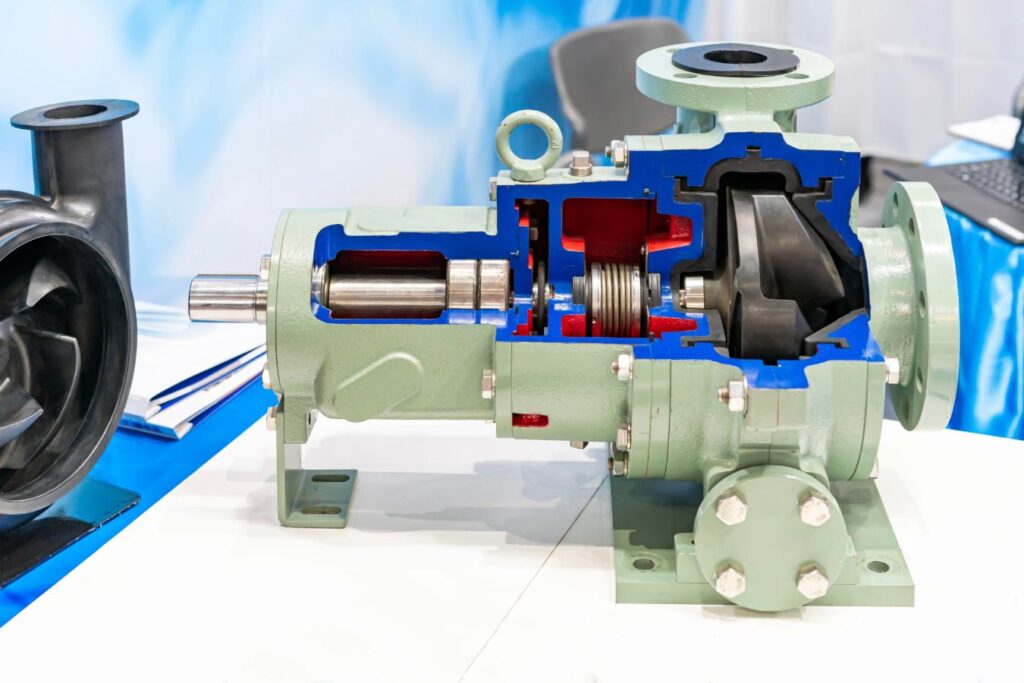

Unlike standard water pumps, slurry pumps are made from robust materials and feature replaceable wear components, such as liners and impellers. Their construction is focused on durability, allowing them to handle fluids containing high concentrations of solids—anything from fine sand and silt to larger rock fragments. Water pumps are not equipped to handle this level of abrasion and would quickly fail under similar conditions.

There are several types of slurry pumps, each suited to specific applications and installation environments:

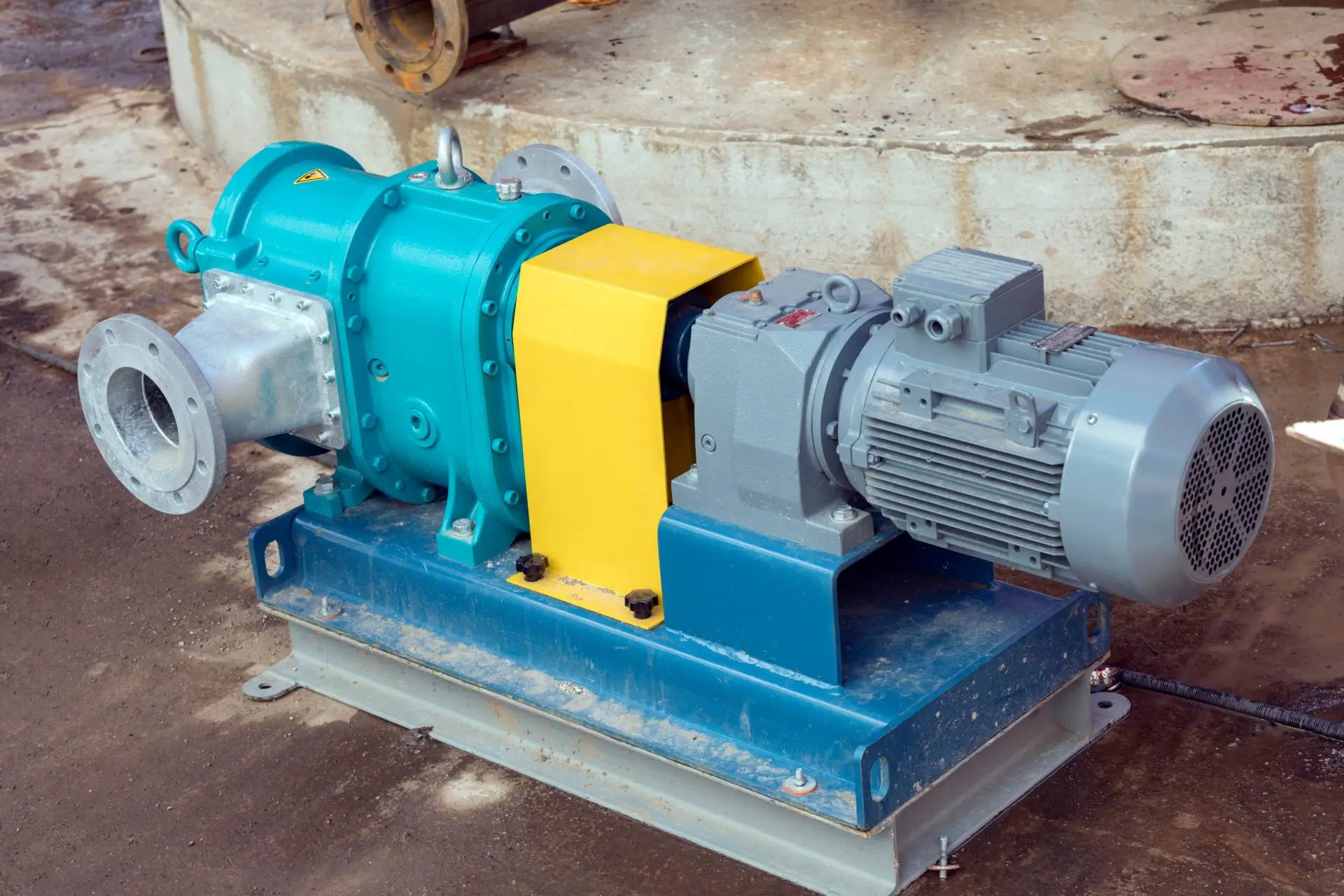

- Centrifugal slurry pumps: The most common type, using a rotating impeller to impart kinetic energy to the slurry.

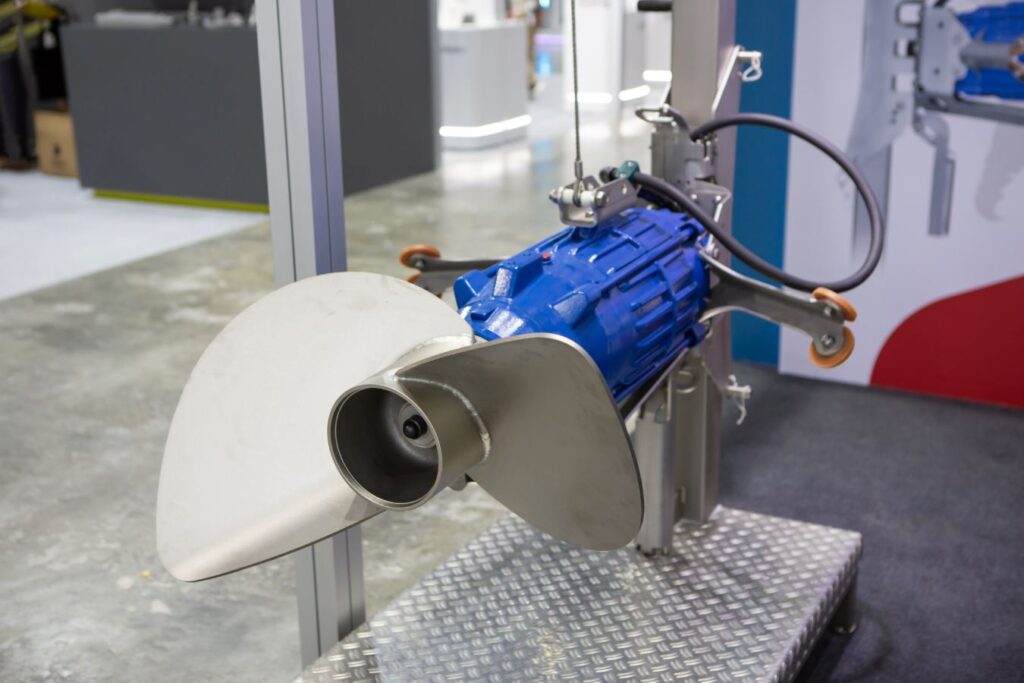

- Submersible slurry pumps are designed to operate while fully submerged, making them ideal for deep pits or underwater applications.

- Horizontal slurry pumps, mounted on the surface, are widely used in high-flow applications and are known for their ease of maintenance.

- Vertical slurry pumps are typically used for sump applications, and they are vertically mounted to handle fluids with high solids content.

Selecting the right type depends on several factors, including slurry composition, pump placement, and required discharge pressure. This is where partnering with knowledgeable slurry pump suppliers becomes critical—they can assess your application and provide a pump solution that ensures both reliability and efficiency.

For temporary or emergency use, many companies opt for slurry pump rental services. A trusted supplier offering slurry pump rental can provide ready-to-deploy equipment without the upfront capital costs of a full purchase. Experienced slurry pump suppliers also offer installation support, technical consultation, and maintenance services, helping you get the most out of your pumping solution.

Applications of Slurry Pumps in Industry

Slurry pumps are essential to a wide range of heavy-duty industrial applications where the reliable transport of solid-laden fluids is crucial. Their ability to handle abrasive, high-density slurries makes them a core component across several sectors, ensuring that material movement is efficient, continuous, and cost-effective.

In the mining and mineral processing industry, slurry pumps are used for tailings disposal, ore transport, and dewatering. These processes involve transporting mixtures of water, minerals, and waste material through long pipelines, often across rugged terrains. Slurry pumps are built to endure extreme wear from abrasive ores and ensure stable flow, reducing the need for frequent downtime or replacement. For remote or short-term mining operations, renting a slurry pump is often a practical option, providing flexible and cost-effective access to high-performance equipment without the need for long-term investment.

In construction and tunneling, slurry pumps play a critical role in managing bentonite slurries, cementitious grouts, and excavated mud. These materials need to be moved quickly and cleanly to prevent delays and structural issues in tunneling operations. Reliable slurry pump suppliers ensure the right configuration is available for these high-pressure, continuous-duty scenarios, where precision and pump durability are essential.

The dredging and marine industries also rely heavily on slurry pumps, particularly for transporting dredged material through pipelines. Whether it’s feeding slurry from a cutterhead dredger or transferring sediment to a containment area, the pump must withstand high levels of abrasives, such as sand and silt. In these environments, equipment redundancy is key, and many contractors turn to slurry pump rental services to quickly scale operations or replace failed units in the field.

Lastly, wastewater and industrial effluent management demand pumps that can handle sludge, grit, and solids without clogging. Here, dependable performance is essential for compliance and operational continuity. Trusted slurry pump suppliers offer not only robust equipment but also maintenance services and parts support, ensuring long-term reliability in these demanding environments.

Across these industries, slurry pumps prove essential to productivity and cost efficiency, especially when backed by knowledgeable suppliers and flexible rental options.

How Slurry Pumps Improve Material Handling Efficiency

Slurry pumps are specifically engineered to optimize material handling efficiency in industries where traditional pumping systems would quickly fail. Their design and performance characteristics directly contribute to increased productivity, reduced maintenance, and improved overall operational reliability, particularly in abrasive and high-solids applications.

One of the primary ways slurry pumps improve efficiency is by significantly reducing clogging and downtime. Unlike standard pumps, slurry pumps are designed with open impeller designs, replaceable liners, and wear-resistant materials, allowing them to handle rocks, sand, sludge, and thick slurries without frequent blockages. This means less time spent on maintenance, more uptime, and fewer interruptions to critical processes.

Another important benefit is energy efficiency over long periods of use. Modern slurry pumps are designed to maintain consistent performance over extended run times, even in harsh conditions. Their ability to move heavy slurries with less energy input, thanks to streamlined hydraulic designs, translates to measurable cost savings over the life of a project or installation.

Slurry pumps also provide precise control over flow rate and pressure, allowing operators to fine-tune pump settings according to the specific demands of the material and system layout. This level of control ensures that pipelines remain free-flowing and system components are not overloaded, which in turn extends the lifespan of the entire operation.

In high-demand environments, where round-the-clock operation is often necessary, slurry pumps enable continuous material handling without compromising performance. This is crucial in sectors such as mining, tunneling, and dredging, where delays can be extremely costly. In such scenarios, businesses often rely on slurry pump rental services to quickly scale up capacity or replace a failed unit without waiting for a lengthy procurement process.

Reliable slurry pump suppliers contribute to this efficiency by offering expertly selected equipment, ensuring compatibility with your system, and providing technical support throughout the pump’s operational lifecycle. Many slurry pump suppliers also offer slurry pump rental options, allowing customers to meet changing project demands without incurring major capital expenditure.

In every case, slurry pumps represent a smart investment in efficient, dependable material transport—especially when supported by responsive suppliers and adaptable rental solutions.

Choosing the Right Slurry Pump: Factors to Consider

Selecting the right slurry pump for your operation requires a careful evaluation of several factors that directly impact performance, durability, and cost-efficiency. Unlike standard fluid handling systems, slurry pumping involves abrasive, viscous, and often corrosive materials, making proper pump selection essential for long-term success.

One of the most important considerations is slurry composition. The percentage of solids, particle size, abrasiveness, and fluid viscosity all influence how the pump must be designed. For example, highly abrasive slurries with large solid particles will require a pump with robust wear-resistant components and a larger impeller clearance to minimize clogging and erosion. Understanding your slurry’s properties ensures the pump will handle the material effectively without compromising flow or lifespan.

Pump material and liner selection also play a critical role in performance and maintenance costs. High-chrome alloys, natural rubber, and polyurethane are commonly used materials for liners and casings, each suited to different types of slurries. For example, natural rubber is effective for handling fine abrasive particles, while high-chrome metal is better for coarse, hard solids. Matching the material to the application prevents premature wear and reduces the need for frequent replacements.

Another critical factor is the pump’s motor power and head capacity. These specifications determine how far and how high the slurry can be transported. Undersizing can lead to inefficient operation, overheating, or failure, while oversizing increases energy consumption and operational costs. Working with experienced slurry pump suppliers can help ensure these calculations are done accurately, based on flow requirements, pipe length, elevation, and system resistance.

Additionally, the pump’s compatibility with existing piping and system layout must be assessed. Factors like inlet/outlet orientation, mounting footprint, and system pressure ratings all affect how easily the new pump can be integrated into your operation. This is especially important for retrofitting or system upgrades.

For temporary or emergency needs, renting a slurry pump provides a cost-effective way to test performance or maintain continuity without a full investment. Partnering with trusted slurry pump suppliers ensures access to tailored solutions, technical support, and reliable equipment that fits your specific application, whether you purchase or rent.

Cost-Effective Options: Slurry Pump Rental vs. Purchase

When facing short-term projects, emergency operations, or seasonal demands, renting a slurry pump can be a highly cost-effective alternative to purchasing the equipment outright. Rental solutions are ideal for applications such as temporary dewatering, rapid-response dredging, or pilot testing new material transport systems. Instead of investing in permanent assets, companies can access the latest technology on demand, only paying for what they need when they need it.

One of the key advantages of renting a slurry pump is the lower upfront cost. Purchasing a high-performance pump can be a capital-intensive investment, especially for smaller operations or contractors managing multiple job sites. Rentals eliminate this financial burden, allowing organizations to scale operations flexibly. In the event of unexpected equipment failure, rentals also offer quick replacement, minimizing downtime and keeping projects on schedule.

Slurry pump suppliers play a crucial role in making rental programs successful. Beyond simply providing the equipment, reputable suppliers offer site assessments, pump sizing, delivery, installation assistance, and even system integration support. Their expertise ensures that the rental pump will match your slurry type, flow rate requirements, and system constraints.

Whether you’re supplementing your fleet or bridging a temporary need, slurry pump rental, backed by knowledgeable slurry pump suppliers, delivers performance and flexibility without long-term commitment.

Conclusion

Slurry pumps play a crucial role in enhancing material handling efficiency across various demanding industries, including mining, construction, dredging, and wastewater management. Their ability to transport abrasive and high-solid-content fluids without frequent clogging or wear makes them indispensable for maintaining operational flow and reducing downtime.

Choosing the right slurry pump, based on slurry composition, pump design, and system layout, is key to maximizing performance and extending equipment life. Whether you’re investing in long-term infrastructure or facing a short-term requirement, options like slurry pump rental provide flexibility and cost savings without sacrificing reliability.

Partnering with experienced slurry pump suppliers ensures not only access to the right equipment but also the technical support needed for proper integration and operation. From customized setups to responsive service, the value of a trusted supplier cannot be overstated. In the end, selecting the right slurry solution ensures safer operations, lower maintenance costs, and a higher return on investment.