Introduction

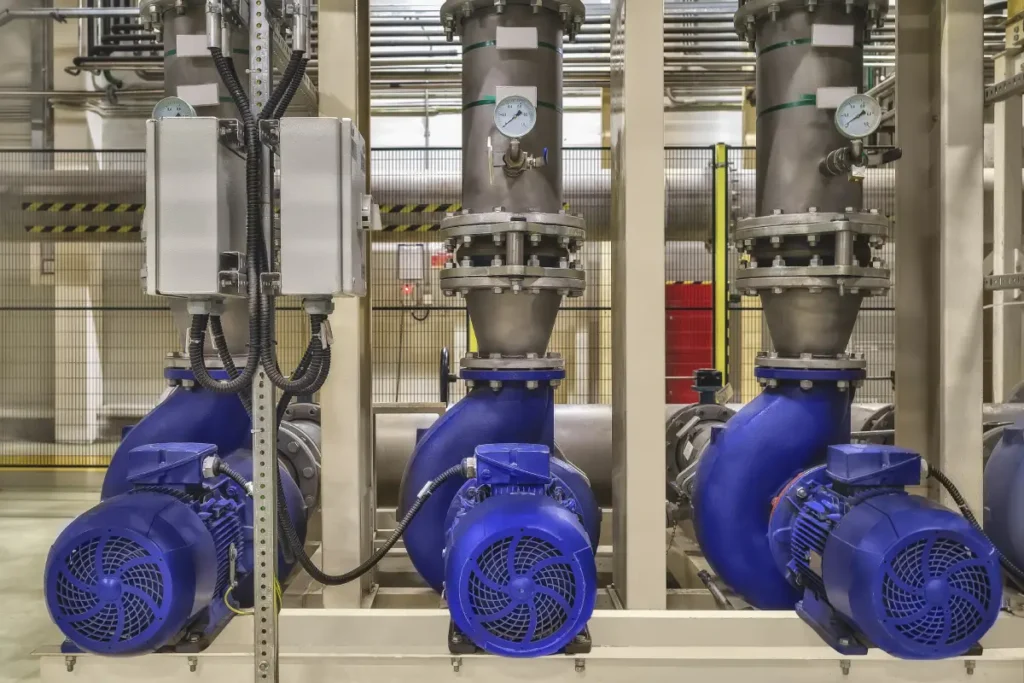

Industrial pumps today serve as precision-engineered assets rather than basic fluid-transfer tools, supporting operations where downtime directly translates into lost production and regulatory risk. In mining, they handle dense slurries with high solids concentration that rapidly degrade conventional equipment. In oil and gas, they manage corrosive fluids and pressure fluctuations that demand exacting material compatibility. Municipal water networks rely on them to sustain continuous flow across ageing infrastructure and variable demand cycles. At the same time, dredging operations depend on pumps that can maintain output even as sediment composition shifts during excavation. These sector-specific challenges require pumps built with advanced metallurgy, wear-resistant hydraulics, and application-matched configurations to ensure stable, long-duration performance in environments where failure is not an option.

Moreover, efficiency and reliability have become two of the most influential factors shaping operational continuity and lifecycle cost. Pumps operating close to their design curve consume significantly less energy, reduce wear on internal components, and maintain predictable flow performance—all of which contribute to stronger ROI. Equally, reliable systems reduce unplanned downtime, prevent damage to secondary equipment, and help control long-term maintenance budgets. For asset managers and procurement teams, these benefits make modern pumps essential to sustaining productivity across large-scale, mission-critical operations.

Amid these rising expectations, organisations increasingly look to experienced industrial pump companies capable of engineering solutions that perform under extreme conditions. PlusPumps is positioned to meet this demand, offering robust, efficiency-focused systems designed specifically for abrasive, high-pressure, and continuous-duty environments. By combining advanced hydraulic engineering with field-tested durability, PlusPumps delivers the level of operational confidence industrial operators require from next-generation pumping technology.

The Efficiency Imperative in Industrial Pumps

Energy consumption has become one of the most important operating cost drivers in large-scale facilities, particularly in industries where fluid handling is constant and demand is high. As production loads rise, even modest inefficiencies in industrial pumps can lead to significant energy waste over time, hurting both profitability and environmental performance. This mounting demand has prompted many businesses to reconsider the technologies that have historically fueled their operations.

Legacy pumping arrangements frequently contribute significantly to these preventable losses. Oversized units operate much below their Best Efficiency Point, putting extra pressure on motors and hastening degradation. Flow imbalance across networks leads to inconsistent performance, while antiquated pipework and high-friction paths force pumps to work harder than necessary. These combined inefficiencies dramatically increase power consumption, which procurement teams can no longer ignore, particularly when comparing solutions from several industrial pump companies.

As energy tariffs rise and sustainability requirements tighten, procurement heads are increasingly prioritizing pump technologies engineered for high efficiency and long-term operational resilience. Modern solutions from leading industrial pump companies now incorporate advanced hydraulics, adaptive controls, and optimized materials, delivering measurable performance improvements. For many organizations, upgrading to energy-optimized industrial pumps is becoming less of a technical choice and more of a strategic imperative driven by cost control and future-focused infrastructure planning.

Innovation #1: Smart Pump Controls (VFDs, IoT, Predictive Monitoring)

Variable Frequency Drives (VFDs) and Variable Speed Drives (VSDs) have changed the way contemporary pump systems work by allowing pump output to be accurately adjusted to real-time demand. Instead of operating at preset rates that may exceed real system needs, these intelligent control systems vary motor speed to ensure appropriate flow and pressure. This not only improves energy performance but also reduces mechanical stress, making them an ideal upgrade for facilities seeking to increase the efficiency of their industrial pumps.

Predictive analytics, like speed control technology, is becoming an essential component of modern pump management. Sensors and data-driven algorithms continuously monitor characteristics such as vibration, temperature, pressure changes, and flow abnormalities. This early visibility allows operators to spot warning signals of wear, cavitation, seal deterioration, or blockage before they worsen. For procurement and maintenance teams, this level of data implies a dramatic change from reactive repairs to proactive asset management.

In real-world scenarios, these improvements result in significant operational advantages. Plants benefit from less downtime, longer equipment lifespans, and more predictable maintenance cycles. As digital monitoring becomes more common in the solutions offered by top industrial pump companies, businesses are embracing these technologies to reduce maintenance costs and improve long-term system reliability.

Innovation #2: Advanced Hydraulic and Centrifugal Pump Designs

Advancements in hydraulic geometries are reshaping the performance standards of modern industrial pumps, particularly in demanding environments where flow consistency and durability are critical. Redesigned impellers, optimized volutes, and smoother internal pathways work together to reduce turbulence and streamline fluid movement. These enhancements not only improve efficiency but also reduce internal wear, enabling industrial pumps to operate more reliably under fluctuating load conditions.

High-efficiency centrifugal configurations are further elevating performance across industrial water, slurry, and mixed-media applications. With refined blade angles, enhanced inlet profiles, and improved hydraulic balancing, these systems maintain stable flow even when dealing with abrasive or variable-density materials. For many operators, such configurations represent a step forward in achieving superior efficiency, an offering increasingly highlighted by leading industrial pump companies.

For high-duty operations, the advantages are especially significant. Enhanced Best Efficiency Point (BEP) stability ensures that industrial pumps run closer to their optimal efficiency range, while improved hydraulic control supports higher throughput without compromising equipment life. These engineering refinements also reduce energy consumption, helping facilities lower operational costs over time. As industrial pump companies continue to integrate advanced geometries and smarter design principles, the performance gap between legacy systems and next-generation industrial pumps becomes increasingly clear.

Innovation #3: New-Generation Materials Enhancing Durability

Material durability is an important factor in pump performance in harsh environments where abrasive slurries, sand, saltwater, and corrosive fluids are used daily. To withstand continual erosion and chemical attack, modern industrial pumps increasingly rely on wear-resistant metals, ceramic-reinforced coatings, and sophisticated composite linings. These specialized materials protect vital components such as impellers, casings, and liners, enabling industrial pumps to operate consistently even under adverse conditions.

Material innovation plays a direct role in extending Mean Time Between Failures (MTBF). High-chromium alloys, duplex and super-duplex stainless steels, tungsten-carbide coatings, and polymer-based barriers significantly reduce wear, thereby minimizing rebuild frequency. This improvement is particularly valuable for operators who manage remote or hard-to-access installations, where every maintenance interval carries both operational and financial impact. As leading industrial pump companies continue to develop more resilient metallurgies and surface technologies, facilities benefit from longer service life and fewer unplanned interruptions.

These advancements are especially important across demanding sectors such as dredging, mine dewatering, industrial wastewater treatment, and offshore fluid handling. In these settings, industrial pumps must sustain high loads while resisting abrasion and corrosion from harsh media. The shift toward smarter material solutions, championed by innovative industrial pump companies, enables operations to achieve greater reliability, lower lifecycle costs, and better protection of assets in high-wear environments.

Innovation #4: Precision Engineering Enhancing Performance

Impeller trimming and the use of optimized impeller geometries have become critical strategies for increasing hydraulic efficiency and ensuring consistent performance across a wide range of operating conditions. Engineers ensure that industrial pumps function closer to their intended duty point by carefully modifying impeller diameter and refining blade profiles. This reduces wasteful energy consumption and internal turbulence. These improvements increase component life while ensuring the pump produces consistent, predictable output. As current performance needs rise, precision-engineered impellers have become a distinguishing element of next-generation industrial pumps utilized in high-load applications.

Mechanical modifications are also important for ensuring long-term system dependability. High-precision bearings reduce friction and provide optimal load distribution, while improved shaft alignment procedures reduce vibration and mechanical stress. Advanced mechanical seals, designed to withstand pressure and temperature changes, as well as abrasive substances, enhance the system’s durability. Leading industrial pump manufacturers are increasingly offering these modifications, indicating an industry move toward components that improve durability and lower lifespan costs.

The combined impact of optimized hydraulics and mechanical enhancements is significant. Facilities experience better vibration control, smoother operation, and greater performance consistency across varying duty cycles. As industrial pump companies continue refining these technologies, operators benefit from industrial pumps that deliver higher reliability, reduced wear, and more efficient operation throughout their service life.

Innovation #5: Condition Monitoring & Reliability-Centered Maintenance

Modern monitoring technologies are changing the way operators oversee the performance and dependability of industrial pumps. Advanced sensors for vibration, flow, pressure, seal leakage, and cavitation detection now give constant feedback on equipment performance. These sensors detect minute differences that were previously hard to detect during normal human inspections, allowing teams to uncover early warning indications before they lead to major failures. As a result, facilities that run several industrial pumps over complex fluid-handling networks may gain a much clearer view of real-time system health.

Real-time monitoring tools enhance this data by providing automatic warnings, performance trend analysis, and continuous condition evaluation. Instead of relying simply on planned inspections, operators may notice problems such as shaft misalignment, seal wear, suction blockages, or hydraulic instability as soon as they arise. This change significantly reduces unplanned outages, ensuring that industrial pumps are available when production demand peaks and that maintenance activities can be planned more precisely. This level of visibility has become critical in high-duty contexts when downtime has severe financial and operational ramifications.

As digital transformation accelerates across the sector, leading industrial pump companies are transitioning from reactive service models to predictive maintenance frameworks. By integrating smart diagnostics, cloud analytics, and AI-driven insights, these providers help users optimize the performance, energy efficiency, and longevity of their industrial pumps. The result is a more resilient pumping ecosystem, where condition-based decisions replace guesswork and the operational continuity of industrial pumps is increasingly assured.

Most Reliable Industrial Pump Types for High-Demand Operations

Multi-stage centrifugal pumps remain a preferred choice for operations that require high head, consistent pressure, and stable output across long distribution networks. Their stacked impeller design enables efficient energy transfer, making them well-suited for industrial water supply, boiler feed applications, and large-scale processing lines. In these settings, industrial pumps must deliver dependable flow under varying load conditions, and multi-stage configurations excel by maintaining performance even as system demands fluctuate.

Precision, controllability, and long service life are the main operating requirements that heavy-duty hydraulic pumps meet. They are ideal for settings where fluid power directly affects process stability and equipment safety, thanks to their ability to modulate pressure precisely. These pumps provide the durability and reactivity needed for mining, construction, and energy-sector applications, as they are designed for severe cycling. The longevity of these industrial pumps becomes a critical component in preserving overall system reliability for facilities that depend on continuous operation.

Self-priming and customized pump designs offer a major benefit in field-based or quick-deployment applications. Quick start-up, minimal setup time, and effective handling of fluids that may contain air, particles, or debris are made possible by their ability to generate suction lift without manual priming. Because of this, they are frequently utilized in mobile industrial setups, emergency dewatering, and portable wastewater systems where dependability and agility are crucial.

The key to long-term success is matching pump type to duty cycle, fluid properties, and operational risk. A number of variables, including temperature, suction conditions, fluid abrasiveness, necessary head, and anticipated load variations, must be evaluated by operators. By selecting the right configuration, industrial pumps can operate at their best in the conditions for which they are designed, providing steady output, consistent efficiency, and reduced mechanical stress throughout their lifetimes.

Conclusion

Industrial pumps’ performance standards are changing due to innovation, ushering in a new era of dependability, efficiency, and lifecycle value. Hydraulic engineering developments, such as improved volutes and reprofiled impellers, are lowering turbulence and enhancing flow uniformity. Concurrently, advances in materials research, such as high-chromium alloys, ceramic coatings, and composite linings, are greatly increasing component durability in high-pressure, abrasive, and corrosive environments. These advancements minimize mechanical stress, which frequently causes early failure, and reduce energy consumption by enabling industrial pumps to operate closer to their intended performance for extended periods.

Smart monitoring technologies further accelerate this shift. With sensors now capable of tracking vibration, pressure, temperature, and seal integrity in real time, operators gain visibility into previously unattainable data. Data-driven analytics detect early signs of wear, misalignment, cavitation, and imbalance, enabling maintenance teams to intervene proactively rather than reactively. As digital capabilities continue to mature, leading industrial pump companies are integrating AI and predictive diagnostics into their systems, enabling performance optimization to be a continuous, automated process.

For organizations aiming to secure long-term value, prioritizing these modern capabilities is no longer optional. Selecting industrial pumps built on advanced hydraulic design, robust materials, and intelligent monitoring ensures more stable operation, lower lifecycle costs, and greater resilience in mission-critical environments.